Revision History

|

O |

Section 2, 3.1 and Table 8.1 |

31 March 2021 |

|

N |

Response to EPDs comment dated 13 January 2021 |

24 February 2021 |

|

M |

Response to EPDs comment dated 4 November 2020 |

10 November 2020 |

|

L |

Response to EPDs comment dated 10 July 2020 |

24 September 2020 |

|

K |

Response to EPDs comment dated 27 May 2020 |

3 June 2020 |

|

J |

Response to EPDs comment dated 6 April 2020 |

24 April 2020 |

|

I |

Section 2, 3.2 and 4.1 |

20 December 2019 |

|

H |

Revise Section 2, 3.1, 4.2, Appendix B, E |

18 March 2019 |

|

G |

Response to EPDs comments dated 29 October 2018, revised Section 4, Section 6, Appendix C, Appendix D, Appendix E & Appendix F |

19 December 2018 |

|

F |

Revised as per provision of silt curtain near coral colonies and revised construction programme |

27 September 2018 |

|

E |

Response to EPDs comment dated 21 August 2018 |

23 August 2018 |

|

D |

Response to EPDs comment dated 11 June 2018 |

25 July 2018 |

|

C |

Response to IECs comment dated 9 May 2018 |

9 May 2018 |

|

B |

Response to IECs comment dated 4 May 2018 |

5 May 2018 |

|

A |

First Issue |

29 Mar 2018 |

|

Rev. |

Description of Modification |

Date |

2 CONSTRUCTION PROGRAMME AND OVERALL SILT CURTAIN INSTALLATION ARRANGEMENT

3.1 Floating Type Silt Curtain

3.2 Cage Type Silt Curtain Type 1

3.3 Cage Type Silt Curtain Type 2

3.4 Cage Type Silt Curtain Type 3

3.5 Cage Type Silt Curtain Type 4

3.6 Cage Type Silt Curtain Type 5

3.7 Cage Type Silt Curtain Type 6

4.3 Laboratory Analytical Methods

4.4 Quality Assurance / Quality Control Requirements

5.1 Training of Marine Mammal Observers

6 SILT CURTAIN OPERATION AND MAINTENANCE

6.1 Approach for Marine Mammal Watching Works

6.2 Visual Inspection of the Waters Surrounded by Silt Curtains

6.3 Regular Inspection of Deployed Silt Curtains

6.4 Regular Inspection of Floating Type Silt Curtain during Opening of Vessel Access

7 SILT CURTAIN REMOVAL / REPOSITIONING

AppendiCEs

B. Typical Section of Floating Type Silt Curtain

C. Specification of the Proposed Geotextile

D. Typical Section of Cage Type Silt Curtains

E. Location of Installation of Floating Type Silt Curtain

F. Silt Curtain Inspection Checklist and Diver Inspection Checklist for Silt Curtain

FIGURES

1. Location of Floating Type Silt Curtain (Before completion of Caisson and Block work Seawall Installation)

2. Location of Floating Type Silt Curtain (After completion of Caisson and Block work Seawall Installation)

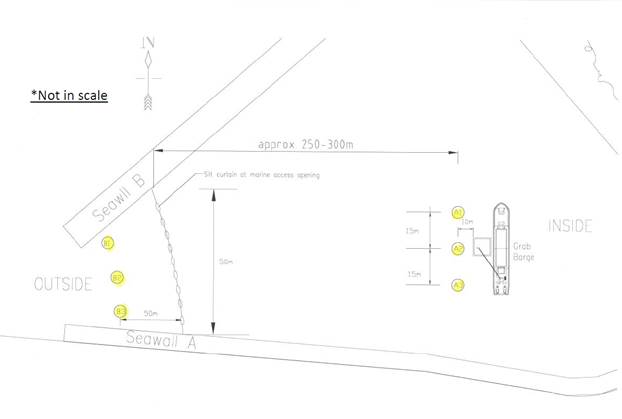

3. Indicative locations of Monitoring Stations for Pilot Test (One double layer of Floating Type Silt Curtain)

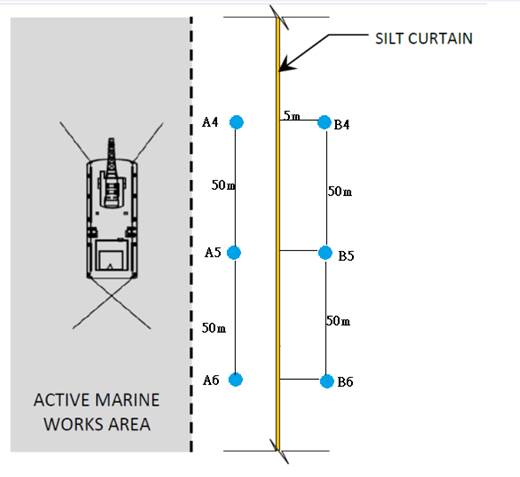

4. Indicative locations of Monitoring Stations for Pilot Test (Two double layer of Floating Type Silt Curtain)

5. Indicative locations of Monitoring Stations for Pilot Test (Cage Type Silt Curtain)

6. Response Procedures of Occurrence of Marine Mammal within Silt Curtain

1 INTRODUCTION

1.1 Background

The Government of Hong Kong SAR will develop the Integrated Waste Management Facilities (IWMF) Phase 1 (hereafter the Project) with incineration to achieve substantial bulk reduction of unavoidable municipal solid waste (MSW) and to recover energy from the incineration process. The IWMF will be on an artificial island to be formed by reclamation at the south-western coast of Shek Kwu Chau. Keppel Seghers Zhen Hua Joint Venture (KSZHJV) was awarded the contract under Contract No. EP/SP/66/12 Integrated Waste Management Facilities Phase 1 to construct and operate the Project.

An environmental impact assessment (EIA) study for the Project has been conducted and the EIA Report was approved under the Environmental Impact Assessment Ordinance on 17 January 2012. An Environmental Permit (EP) (EP No.: EP-429/2012) was granted to EPD on 19 January 2012 for the construction and operation of the Project. Subsequently, the EP was amended (EP No.: EP-429/2012/A) and a further EP (FEP) (EP No.: FEP-01/429/2012/A) was granted to the Keppel Seghers Zhen Hua Joint Venture (KSZHJV) on 27 December 2017.

Pursuant to Clause 2.6 of the FEP, a silt curtain deployment plan shall be developed and deposited with the Director of Environmental Protection at least 1 month before the commencement of marine works of the Project.

1.2 Purpose & Scope

As specified in Condition 2.6 of the FEP:

At least 1 month before the commencement of marine works of the Project, 3 hard copies and 1 electronic copy of a silt curtain deployment plan shall be deposited with the Director. The silt curtain deployment plan shall include the construction programme and details on the design, operation and maintenance of silt curtain(s) for marine works.

This Silt Curtain Deployment Plan (SCDP) has been prepared in accordance with the FEP requirements and details the requirements for implementation of silt curtains during the Project construction phase. The key items covered by this Plan include:

Ÿ Summary of marine works requiring deployment of silt curtains

Ÿ Key components and design specifications for floating and cage-type silt curtains

Ÿ Requirements for installation, operation, maintenance and removal / re-deployment of the silt curtains during construction

Ÿ Methodology for the pilot test on silt curtain efficiency

2 CONSTRUCTION PROGRAMME AND OVERALL SILT CURTAIN INSTALLATION ARRANGEMENT

In general, one double layers of floating type silt curtain will be deployed at the opening of the seawall at the western side of Artificial Island.

Marine filling works within reclamation area will be commenced when the installation of block work seawall near the shoreline have been completed for 310m. In other words, the installation of block work seawall between Vertical Seawall Chainage S_CH0 and Vertical Seawall Chainage S_CH310 shall be completed. In addition, the precast caissons at Seawall A between Chainage SB_CH250 and SB_CH580 and at Seawall B between Chainage Q_CH0 and Q_CH388 shall be completed. Therefore, as a temporary measure, one double layers of floating type silt curtain will be installed at the eastern side of Artificial Island after the installation of block work seawall and Caisson at Seawall A and Seawall B as mentioned above. The overall silt curtain installation arrangement can refer to Figure 1 of Appendix E.

After completion of seawall construction (except the portion left for marine access at the western side of Artificial Island), the temporary silt curtain located at the eastern side of Artificial Island will be removed. The overall silt curtain removal arrangement can refer to Figure 2 of Appendix E.

Two double layers of floating type silt curtain will be deployed in the vicinity of coral colonies when the site is carrying out marine works that can affect fine contents on marine water such as laying sand blanket, laying Grade 200 and Grade 400 rock, dredging works, filling work below +2.5mPD at the reclamation area prior to the complete installation of caissons at marine access and operating of deep cement mixing. Cage typed silt curtain will be deployed during laying sand blankets, dredging works, filling works during seawall construction and operating of deep cement mixing. Cage Type silt curtain is equivalent to frame type silt curtain as stated in Further Environmental Permit Clause 2.17 to 2.19.

A brief programme showing the tentative commencement and completion dates of the major marine works are enclosed in Appendix A.

3 SILT CURTAIN DESIGN

3.1 Floating Type Silt Curtain

All floating silt curtains shall comprise at least the following components:

Ÿ Silt Curtain fabric

Ÿ Flotation

Ÿ Ballast chain

Ÿ Seams and Joints

Ÿ Anchors

Ÿ Warning lights / marker buoys

Silt Curtain Fabric

For silt curtains, the fabric material shall comprise a geotextile such as woven polypropylene or reinforced polyvinyl chloride (PVC) membrane. Impermeable fabrics are not recommended due to the excessive pressure that would be induced on the curtain due to tidal conditions, hence the fabric shall have a suitably low permeability that allows water to pass through under pressure, but will retain suspended solids. The fabric including seams and connecting parts shall have adequate tensile strength to withstand the pressures induced by the wind, wave and sea current conditions at the location to be deployed.

Floatation

The floatation device shall comprise flexible and buoyant units contained within a floatation sleeve or collar that is attached to the silt curtain. The buoyancy of the floatation units shall be adequate to support the full weight of the curtain including the pressure weight induced by tidal currents acting on the silt curtain surface. A freeboard of at least 10cm shall be maintained above the water surface at all times.

Ballast Chain

The ballast chain (or load lines) shall comprise a steel chain that is incorporated into the bottom hem of the silt curtain. The chain shall be sufficiently weighted to hold the curtain in a vertical position. Connecting devices from the load lines to connecting joints of the silt curtain shall be able to develop the full breaking strength of the chain.

Seams and Joints

Seams of the silt curtain fabric shall be heat sealed and shall develop the full strength of the fabric. Jointing devices such as ropes, chains and shackles shall be made of materials with adequate strength and shall not limit the full strength of the silt curtain fabric.

Anchors

Anchors shall comprise either dig type (e.g. stakes, grappling hook, plow or fluke-type) or weight type (e.g. concrete blocks) with adequate hold / weight to retain the silt curtain in the same position relative to the seabed without interfering with the action of the silt curtain. Lateral anchors (one on either side of the silt curtain) shall be attached to a floating anchor buoy via an anchor line, which connects to the top of the silt curtain. Anchor spacing should be between 15 to 30 m apart. For areas with faster current velocity, closer spacing shall be adopted as necessary to stabilize the silt curtain.

Warning Lights / Marker Buoys

To warn other marine vessels not to approach or run into the silt curtains, yellow marker buoys fitted with yellow flashing lights shall be used to indicate the position of the anchors and silt curtain system. The buoys and lights shall be located on both sides of the silt curtain at regular intervals (no more than 60m apart) along the entire length of silt curtain.

Silt Curtain Depth

The depth (vertical length from the waters surface to the bottom) of the silt curtain shall be sized to the water depth at the location of deployment. The base of the silt curtain skirt shall be anchored to within 30cm of the seabed even during high tides, hence adequate depth of silt curtain shall be allowed in the total silt curtain depth to cater for tidal changes. Given that the tidal range at the Project area can reach >2m, the base of the silt curtain may be affected by deposition of sediment during low tides. Design of the silt curtain shall take into account the potential additional drag pressure on the silt curtain due to sediment deposition at low tide.

Three sets of floating type silt curtain shall be installed.

1. One double layers of floating type silt curtain shall be installed at the opening of the marine access at the western side of Artificial Island;

2. Marine filling works within reclamation area will be commenced when the installation of block work seawall near the shoreline have been completed for 310m. In other words, the installation of block work seawall between Vertical Seawall Chainage S_CH0 and Vertical Seawall Chainage S_CH310 shall be completed. In addition, the precast caissons at Seawall A between Chainage SB_CH250 and SB_CH580 and at Seawall B between Chainage Q_CH0 and Q_CH388 shall be completed. Therefore, as a temporary measure, one double layers of floating type silt curtain will be installed at the eastern side of Artificial Island after the installation of block work seawall and Caisson at Seawall A and Seawall B as mentioned above. The overall silt curtain installation arrangement can refer to Figure 1 of Appendix E. After completion of seawall construction (except the portion left for marine access at the western side of Artificial Island), the temporary silt curtain located at the eastern side of Artificial Island will be removed. The overall silt curtain removal arrangement can refer to Figure 2 of Appendix E; and

3. Two double layers of floating type silt curtain shall be installed in the vicinity of coral colonies when the site is carrying out marine works that can affect fine contents on marine water such as laying sand blanket, laying Grade 200 and Grade 400 rock, dredging works, filling work below +2.5mPD at the reclamation area prior to the complete installation of caissons at marine access and operating of deep cement mixing.

The typical section of the proposed floating type silt curtain is attached in Appendix B. Specification of the proposed geotextile for the silt curtain is attached in Appendix C.

Cage type silt curtain Type 1 shall mainly comprise the geotextile fabric with ballast chain / weight, a metal frame and associated connectors to affix the silt curtain to the frame. The frame shall be made of non-corrosive metal and properly designed to achieve structural integrity of the silt curtain.

The geotextile fabric shall be mounted and/or affixed to all four sides of the frame using seamed joints with sufficient overlap to prevent leakage of suspended solids. The silt curtain shall contain a roll up mechanism to enable the geotextile fabric to be rolled up when not in use. The design of the mechanism must enable the geotextile fabric to remain attached to the sides of the frame during roll up and roll down (i.e. prevent billowing of the fabric away from the cage frame).

Both the length of the frame and the geotextile fabric shall be measured and cut to fit the water depths at the location of deployment. The exact length shall be flexible to cater for changes in tidal level.

Cage type silt curtain Type 1 shall be used by vessels laying sand blanket, laying Grade 200 and Grade 400 rock and dredging by using a closed grab method. Laying of sand blanket shall be carried out by a bottom dumping method to prevent localized overloading of the seabed and potential instability as well as minimizing loss of fines when placing the sand. The proposed method would allow sand to be discharged to a point near the seabed where current dispersion would be low. In addition, dredging works shall be carried out by closed grab dredger, each of grab size of not more than 2m3.

The typical section of the different cage type silt curtains are attached in Appendix D. Specification of the proposed geotextile is attached in Appendix C.

3.3 Cage Type Silt Curtain Type 2

Cage type silt curtain Type 2 shall mainly comprise the geotextile fabric with ballast chain / weight. Metal rods and associated connectors to affix the silt curtain to the electric winches installed at the boundary of DCM barge. The metal rods shall be made of non-corrosive metal and properly designed to achieve structural integrity of the silt curtain.

The geotextile fabric shall be mounted and/or affixed to all four sides of the DCM barges using seamed joints with sufficient overlap to prevent leakage of suspended solids. The silt curtain shall contain a roll up mechanism, by electric winch, to enable the geotextile fabric to be rolled up when not in use. The design of the mechanism must enable the geotextile fabric to remain attached to the sides of the DCM barge during roll up and roll down (i.e. prevent billowing of the fabric away from the DCM barge).

Both the length of the frame and the geotextile fabric shall be measured and cut to fit the water depths at the location of deployment. The exact length shall be flexible to cater for changes in tidal level.

Cage type silt curtain Type 2 shall be used by DCM barge as a secondary layer of silt curtain while conducting DCM works.

The typical section of the different cage type silt curtains are attached in Appendix D. Specification of the proposed geotextile is attached in Appendix C.

3.4 Cage Type Silt Curtain Type 3

Cage type silt curtain Type 3 shall comprise of several layers of hollow boxes made up of metal plates. The total length of hollow box can be adjusted by using telescopic method. Electric winches shall be used to move the hollow box upward or downward so as to reach the seabed. The metal plates shall be made of non-corrosive metal and properly designed to achieve structural integrity of the silt curtain.

Cage type silt curtain Type 3 shall be used by DCM barge in the vicinity of drilling rod as a primary layer of silt curtain while conducting DCM works.

The typical section of the different cage type silt curtains are attached in Appendix D.

3.5 Cage Type Silt Curtain Type 4

Cage type silt curtain Type 4 shall mainly comprise the geotextile fabric with ballast chain / weight, a metal frame and associated connectors to affix the silt curtain to the frame. The frame shall be made of non-corrosive metal and properly designed to achieve structural integrity of the silt curtain.

Double layers geotextile fabric shall be mounted and/or affixed to all four sides of the frame using seamed joints with sufficient overlap to prevent leakage of suspended solids. The silt curtain shall contain a roll up mechanism to enable the geotextile fabric to be rolled up when not in use. The design of the mechanism must enable the geotextile fabric to remain attached to the sides of the frame during roll up and roll down (i.e. prevent billowing of the fabric away from the cage frame).

Both the length of the frame and the geotextile fabric shall be measured and cut to fit the water depths at the location of deployment. The exact length shall be flexible to cater for changes in tidal level.

Cage type silt curtain Type 4 shall be used by spreader pontoon / pelican barge / sand pumping barge while conducting reclamation by using sand pumping pipe. Reclamation shall be carried out by a bottom dumping method to prevent localized overloading of the seabed and potential instability as well as minimizing loss of fines when placing the sand. The proposed method would allow sand to be discharged to a point near the seabed where current dispersion would be low.

The typical section of the different cage type silt curtains are attached in Appendix D. Specification of the proposed geotextile is attached in Appendix C.

3.6 Cage Type Silt Curtain Type 5

Cage type silt curtain Type 5 shall mainly comprise the geotextile fabric with ballast chain / weight, a metal chute with tremie pipes and associated connectors to affix the silt curtain to the metal chute. The metal chute with tremie pipes shall be made of non-corrosive metal and properly designed to achieve structural integrity of the silt curtain.

The geotextile fabric shall be mounted and/or affixed to all four sides of the metal chute with tremie pipes using seamed joints with sufficient overlap to prevent leakage of suspended solids. The silt curtain shall contain a roll up mechanism to enable the geotextile fabric to be rolled up when not in use. The design of the mechanism must enable the geotextile fabric to remain attached to the sides of the metal chute with tremie pipes during roll up and roll down (i.e. prevent billowing of the fabric away from the metal chute with tremie pipes).

Both the length of the metal chute with tremie pipes and the geotextile fabric shall be measured and cut to fit the water depths at the location of deployment. The exact length shall be flexible to cater for changes in tidal level.

Cage type silt curtain Type 5 shall be used by spreader pontoon / pelican barge while conducting reclamation without using sand pumping pipe. Reclamation shall be carried out by a bottom dumping method to prevent localized overloading of the seabed and potential instability as well as minimizing loss of fines when placing the sand. The proposed method would allow sand to be discharged to a point near the seabed where current dispersion would be low.

The typical section of the different cage type silt curtains are attached in Appendix D. Specification of the proposed geotextile is attached in Appendix C.

3.7 Cage Type Silt Curtain Type 6

Cage type silt curtain Type 6 shall mainly comprise the geotextile fabric with ballast chain / weight and associated connectors to affix the silt curtain to the caissons.

The geotextile fabric shall be mounted and/or affixed to caissons with sufficient overlap to prevent leakage of suspended solids. The silt curtain shall contain a roll up mechanism to enable the geotextile fabric to be rolled up when not in use. The design of the mechanism must enable the geotextile fabric to remain attached to the sides of caissons during roll up and roll down.

Both the length of the caissons and the geotextile fabric shall be measured and cut to fit the water depths at the location of deployment. The exact length shall be flexible to cater for changes in tidal level.

Cage type silt curtain Type 6 shall be used during seawall filling works. Reclamation shall be carried out by a bottom dumping method to prevent spraying out of fines out of the caissons.

The typical section of the different cage type silt curtains are attached in Appendix D. Specification of the proposed geotextile is attached in Appendix C.

4 SILT CURTAIN PILOT TEST

4.1 Pilot Test Arrangement

The pilot test is proposed to be carried out during the early stage of construction with highest current speed conditions, covering both flood and ebb tide for one - two week including 3 sampling days for silt curtain efficiency testing.

During the silt curtain efficiency testing, sand blanket laying or operating of deep cement mixing works shall be actively conducted within the works areas protected by the silt curtains to be tested, and shall be operating at close to the maximum productivity. The sand blanket laying or operating of deep cement mixing works shall be located as close to the silt curtain boundary as practicable.

During the whole pilot test, the surrounding environment should be controlled as far as practicable such that there would be no other major SS-generating construction activity operating concurrently, or marine vessel movements in the near vicinity.

4.2 In-situ Monitoring

4.2.1 Monitoring Locations

Floating Type Silt Curtain

The water monitoring of the pilot test will be conducted at a total of six monitoring stations, i.e. three within marine works area and three outside the silt curtain. The locations of the sampling stations are described in Table 4.1, Table 4.2, Figure 3 and Figure 4.

|

Monitoring Stations |

Location |

Description |

|

A1 |

Within Marine Works Area |

The floating type silt curtain is 50m wide only. The distance between the inside stations (A1 to A3) will be adjusted according to the actual dimension of the floating type silt curtain on the day of the test. |

|

A2 |

||

|

A3 |

||

|

B1 |

Outside Silt Curtain |

The floating type silt curtain is 50m wide only. The distance between the outside stations (B1 to B3) will be adjusted according to the actual dimension of the floating type silt curtain on the day of the test and located within approximately 50m from the silt curtain boundary. |

|

B2 |

||

|

B3 |

Figure 3 Indicative locations of Monitoring Stations for Pilot Test (One double layer of floating Type Silt Curtain)

Table 4.2 Locations of Monitoring Stations for Pilot Test (for two double layers of Floating type silt curtain)

|

Monitoring Stations |

Location |

Description |

|

A4 |

Within Marine Works Area |

Three monitoring stations spaced at approximately 50m from each other and located between the marine works and the silt curtain boundary |

|

A5 |

||

|

A6 |

||

|

B4 |

Outside Silt Curtain |

Three monitoring stations spaced at approximately 50m from each other and located within approximately 5m from the silt curtain boundary |

|

B5 |

||

|

B6 |

Figure 4 Indicative locations of Monitoring Stations for Pilot Test (Two double layer of Floating Type Silt Curtain)

Cage Type Silt Curtain

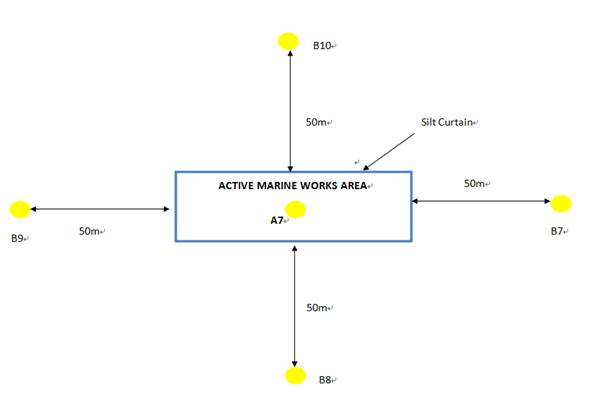

The water monitoring of the pilot test will be conducted at a total of five monitoring stations, i.e. one inside the cage and four outside the silt curtain. The locations of the sampling locations are described in Table 4.3 and Figure 5.

Table 4.3 Locations of Monitoring Stations for Pilot Test (for cage type silt curtain)

|

Monitoring Stations |

Location |

Description |

|

A7 |

Within Marine Works Area |

One monitoring station will be located inside the cage |

|

B7 |

Outside Silt Curtain |

Four monitoring stations located at four sides of silt curtain and within approximately 50m from the silt curtain boundary |

|

B8 |

||

|

B9 |

||

|

B10 |

Figure 5 Indicative locations of Monitoring Stations for Pilot Test (Cage Type Silt Curtain)

4.2.2 Water Sampling Equipment

For in-situ monitoring, a turbidimeter (HACH 2100Q or equivalent) will be used to measure turbidity. A sampler will be used to collect water samples for laboratory analysis of suspended solids.

4.2.3 Turbidity

Turbidity will be measured in-situ by the nephelometric method. The instrument will be portable and weatherproof using a DC power source complete with cable, sensor and comprehensive operation manuals. The equipment will be capable of measuring turbidity between 0-1000 NTU. The probe cable will not be less than 25m in length.

4.2.4 Water Depth Detector

A portable, battery-operated echo sounder will be used for the determination of water depth at each designated monitoring station. This unit can either be hand held or affixed to the underside of the survey boat, if the same vessel is to be used throughout the monitoring programme.

4.2.5 Position System

A hand held Global Positioning System (GPS) will be used to ensure that the correction location has been selected prior to sample collection.

4.2.6 Current Velocity and Direction

A Valeport 106 or equivalent current meter will be used for measuring current velocity and direction to verify the exact location of the impact monitoring stations and control stations.

4.2.7 Suspended Solids

A water sampler, consisting of PVC or glass cylinder of a capacity of not less than two litres which can be effectively sealed with cups at both ends will be used. The water sampler will have a positive latching system to keep it open and prevent premature closure until released by a messenger when the sampler is the selected water depth.

4.2.8 Sample Container and Storage

Following collection, water samples for laboratory analysis will be stored in high density polythene bottles with no preservatives added, packed in ice (cooled to 4°C without being frozen), delivered to the laboratory and analyzed as soon as possible.

4.2.9 Calibration of In-Situ Instruments

The turbidimeter should be checked and calibrated before use. Turbidimeter should also be certified by a laboratory accredited under Hong Kong Laboratory Accreditation Scheme (HOKLAS) or other international accreditation scheme, and subsequently re-calibrated at 3 monthly intervals throughout all stages of the pilot test. Responses of turbidimeter will be checked with certified standard solutions before each use.

For the in-situ calibration of field equipment, the BS 1427:2009, Guide to on-site test methods for the analysis of waters will be observed.

Sufficient stocks of spare parts will be maintained for replacements when necessary. Backup monitoring equipment will also be made available so that monitoring can proceed uninterrupted even when some equipment is under maintenance, calibration, etc.

Table 4.4 summarizes the equipment used in the water quality monitoring program of pilot tests.

Table 4.4 Water Quality Monitoring Equipment

|

Equipment |

Model |

Monitoring Parameters / Use |

Quantity |

|

Water Sampler |

Kahlsico Water Bottle Model 135DW 150 or equivalent |

Collection of water sample |

2 |

|

Turbidimeter |

HACH 2100Q or equivalent |

Measurement of turbidity |

2 |

|

Monitoring Position Equipment |

Magellan handheld GPS Model Triton 400/Garmin Model eTrex 10 or equivalent |

Determination of water quality monitoring stations |

1 |

|

Sonar Water Depth Detector |

Garmin Fishfinder 140 or equivalent |

Determination of water depth |

1 |

|

Current Meter |

Valeport 106 or equivalent |

Measurement of current velocity and direction |

1 |

4.2.10 Monitoring Methodology

The monitoring stations will be accessed by the guide of a hand held digital Global Positioning System (GPS) during water quality monitoring of pilot test. The depth of the monitoring location will be measured using depth meter in order to determine the sampling depths. Afterwards, the water sampler will be lowered to the predetermined depths (1m below water surface, mid-depth and 1m above seabed) and the collected water samples shall be decanted into the sample cells of the turbidimeter for analysis of turbidity. At each measurement, two consecutive measurements of in-situ parameters will be taken. Where the difference in the value between the first and second readings of each set was more than 25% of the value of the first reading, the reading will be discarded and further readings will be taken.

Water samples for SS (mg/L) measurements will be collected at the same depths.

Water sampler will be lowered into the water to the required depths of sampling. Upon reaching the pre-determined depth, a messenger to activate the sampler will then be released to travel down the wire. The water sample will be sealed within the sampler before retrieving. At each station, water samplers at three depths (1m below the water surface, mid depth and 1m above the seabed) will be collected accordingly. Water samples will be stored in a cool box and kept at less than 4°C but without frozen and sent to the laboratory as soon as possible. In addition, field information will also be recorded. Adequate water samples (about 1L) for laboratory measurements will be collected.

The water quality parameters to be monitored are tabulated below in Table 4.5.

Table 4.5 Water Quality Parameters to be tested during Pilot Test

|

Water Quality Parameters |

Pilot Test |

|

Turbidity |

x |

|

Suspended Solids (SS) |

x |

|

Water depth |

x |

|

Current Velocity and direction |

x |

4.3 Laboratory Analytical Methods

Analysis of suspended solids (SS) will be conducted by laboratory accredited under HOKLAS or other international accredited laboratory, and comprehensive quality assurance and control procedures in place will be carried out in order to ensure quality and consistency in results. The testing method and limit of reporting are provided in Table 4.6.

Table 4.6 Laboratory Analysis for Water Samples

|

Parameter |

Proposed Method |

Reporting Limit |

|

Suspended Solids |

APHA 2540D |

1.0 mg/L |

4.4 Quality Assurance / Quality Control Requirements

4.4.1 Decontamination Procedures

Water sampling equipment used during the course of the monitoring programme will be decontaminated by manual washing and rinsed clean seawater / distilled water after each sampling event. All disposal equipment will be discarded after sampling.

4.4.2 Sampling Management and Supervision

Water samples will be dispatched to the testing laboratory for analysis as soon as possible after the sampling. All samples will be stored in a cool box and kept at less than 4°C but without freezing. All water samples will be handled under a chain of custody protocols and relinquished to the laboratory representatives at locations specified by the laboratory.

4.5 Review and Report

The effectiveness of the proposed silt curtain system can be calculated based following equation:

(SSinside SSoutside) / SSinside x 100% ≥ 80%

The results of the pilot test and the recommendations and modifications for the silt curtain system will be submitted to the Supervising Officer (SO), Independent Environmental Checker (IEC) and Environmental Team Leader (ETL) for review.

5 SILT CURTAIN INSTALLATION

Silt curtains shall be installed completely before commencement of any marine works requiring silt curtains. Prior to installation of silt curtains, the KSZHJV shall undertake a thorough check for defects and / or damages particularly in the silt curtain fabric, at the seams, and at the jointing / connector locations. Any defects and / or damages shall be rectified before commencing installation. In addition, trained Marine Mammal Observer(s) (MMO(s)) shall check whether silt curtains are ready, well prepared and operated without any obvious damage. MMO(s) shall confirm the presence of the relevant frontline staff of KSZHJV and its sub-contractors and engineers on board to ensure the effective communication, coordination and implementation so as to response to any incidents involving marine mammals within the waters surrounded by the cage type / floating type silt curtain and the work areas. Also there are lookout points at an elevated level of each barge, clear and safe access at the edges of the barge for inspection during dredging / sand blanket laying, DCM works, seawall filling and reclamation works, provision of sufficient lighting is required if working at night.

5.1 Training of Marine Mammal Observers

Training sessions for MMO(s) shall be conducted by marine mammal specialist, Dr. Samuel Hung, Dr. Lindsay Porter, Ms. Julia Chan or someone with equivalent qualifications, with briefing materials provided as guidelines, instructing adequate knowledge of all requirements for observing marine mammal and appropriate actions to be taken. Competence checking by ET shall be provided to the trained MMO(s) and the training frequency shall follow the approved Marine Mammal Watching Plan.

As the frontline staff of KSZHJV or its sub-contractors, i.e. foremen, site agent, superintendents and engineers would involve in the installation of silt curtain, briefings for these personnel will be provided by the trained MMO(s) during induction trainings to get familiar with the requirements and duties of MMO(s) so as to assist on marine mammal observations within waters surrounded by silt curtains and taking necessary action when there is marine mammal trapped by silt curtain. Refresh briefings will be provided to all frontline staff once every 6 months. The briefing and training records will be provided to ETL, IEC and SO for audit and record.

5.2 Floating Silt Curtains

The furled floating silt curtains shall be launched into the sea by derrick / crane boats / seawalls and floated into position. Anchors shall be carefully lowered to the seabed at the specified intervals. Care shall be taken to ensure that lateral anchor points are in the correct positions prior to attaching the anchor lines / anchor buoy to the silt curtain. After attaching the silt curtain to the anchors and before unfurling the silt curtains, a check shall be conducted on the lay of the curtain to confirm the positioning and slack allowances are correct. Where necessary, final adjustments should be made to the anchors, before the furling lines are released to allow the silt curtain skirt to drop. Where base anchors are also required, connection of the anchor lines to the silt curtain shall be done by divers after unfurling the silt curtain.

In order to avoid the entrance of marine mammals into the works area through the opening at silt curtains for vessel access, and the subsequent potential impacts including increase in stress level in marine mammals due to underwater noise and chance of collision with working vessels, the openings for vessel access at the silt curtains should be restricted to about 50m to minimize the risk of accidental entrance by marine mammal. The silt curtain installed in the vicinity of coral colonies is mainly served to reduce the impact of suspended solids generated from construction activities to the adjacent coral colonies. The location of installation of floating type silt curtain is attached in Appendix E.

During the installation process of floating type silt curtains, in order to avoid the accidental entrance and entrapment of marine mammals within the silt curtains, a monitored exclusion zone of 250m radius from silt curtain should be implemented. The exclusion zone should be closely monitored by an experienced marine mammal observer (MMO) for at least 30 minutes before the start of installation process. If a marine mammal is noted within the exclusion zone, all marine works should stop immediately and remain idle for 30 minutes, or until the exclusion zone is free from marine mammals. The experienced marine mammal observer should be well trained to detect marine mammals. Binoculars should be used to search the exclusion zone from an elevated platform with unobstructed visibility. The marine mammal observer(s) shall be independent of the KSZHJV and shall form part of the Environmental Team and have the power to call-off construction activities.

In addition, as marine mammals cannot be effectively monitored within the proposed monitored exclusion zone at night, or during adverse weather conditions (i.e. Beaufort 5 or above, visibility of 300 meters or below), marine works requiring the exclusion zone monitoring, should be avoided under weather conditions with low visibility as much as possible. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision device will be used. For the marine mammal monitoring during adverse weather, the contractor shall also confirm the visibility of lookout point for effective implementation of the exclusion zone monitoring, safety of MMO(s) and practicability of deployment of silt curtain, otherwise marine works requiring the exclusion zone monitoring shall be ceased.

5.3 Cage Type Silt Curtains

The assembled cage frame shall be securely attached to the section of the construction vessel involved in the marine works (e.g. around the grab of the grab dredger). The rolled up silt curtains attached to the cage frame should be lowered to seabed level after the frame position has been fixed and the vessel is in the correct location for the marine works.

During the installation process of cage type silt curtains, in order to avoid the accidental entrance and entrapment of marine mammals within the silt curtains, a monitored exclusion zone of 250m radius from silt curtain should be implemented. The exclusion zone should be closely monitored by an experienced marine mammal observer (MMO) for at least 30 minutes before the start of installation process. If a marine mammal is noted within the exclusion zone, all marine works should stop immediately and remain idle for 30 minutes, or until the exclusion zone is free from marine mammals. The experienced marine mammal observer should be well trained to detect marine mammals. Binoculars should be used to search the exclusion zone from an elevated platform with unobstructed visibility. The marine mammal observer(s) shall be independent of the KSZHJV and shall form part of the Environmental Team and have the power to call-off construction activities.

In addition, as marine mammals cannot be effectively monitored within the proposed monitored exclusion zone at night, or during adverse weather conditions (i.e. Beaufort 5 or above, visibility of 300 meters or below), marine works requiring the exclusion zone monitoring, should be avoided under weather conditions with low visibility as much as possible. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision device will be used. For the marine mammal monitoring during adverse weather, the contractor shall also confirm the visibility of lookout point for effective implementation of the exclusion zone monitoring, safety of MMO(s) and practicability of deployment of silt curtain, otherwise marine works requiring the exclusion zone monitoring shall be ceased.

6 SILT CURTAIN OPERATION AND MAINTENANCE

On board supervisors will be assigned to check the condition of the silt curtain before commencement of works every day. An inspection checklist will be prepared and filled in by the site supervisors. All checklists will be kept on site for record purpose. The sample of Silt Curtain Daily Inspection Checklist and Diver Inspection Checklist for Silt Curtain are attached in Appendix F.

For the tentative arrangement of silt curtain under adverse weather, the silt curtain will not be temporary removed. However, related works will be suspended immediately if silt curtain is found any damage. The damaged silt curtain shall be lifted up from water by grab dredger / derrick barge. Double line sew a new piece of geotextile to the existing geotextile to cover the damaged area. The overlapping length shall be at least 300mm. The marine works involving the requirement for using of silt curtain shall only be commenced after the damaged silt curtain is repaired.

Refuse around the silt curtains will be collected at regular intervals on a daily basis so that water behind the silt curtains will be kept free from floating debris.

Sufficient spare geotextiles will be kept on site for replacing of damaged silt curtains. The spare geotextiles shall be covered with tarpaulin sheets to avoid direct contact with water and sunlight.

Underwater silt curtain inspection will be conducted by diver after installation / re-installation / relocation of silt curtains / suspected sediment release due to ineffectiveness of silt curtain (e.g. from the results of environmental monitoring of suspended solids by the ET). Diver inspections shall cover at least a 10m length of silt curtain or one whole silt curtain panel (whichever is greater) at each diving location, and at intervals of at least every 200m along the length of silt curtains deployed. The diver inspections shall check that the silt curtain fabric is intact, the silt curtain depths and anchor positions are correct, and there is no damage / breakage in anchor and load lines. Photographic records shall be taken during each underwater inspection. All identified defects / damage shall be photographed and the position recorded on GPS to enable the affected areas to be subsequently located for in-situ repair where appropriate.

6.1 Approach for Marine Mammal Watching Works

Detailed marine mammal watching works shall refer to the approved Marine Mammal Watching Plan and Detailed Monitoring Programme on Finless Porpoise under FEP 01/420/2012/A. The key components of marine mammal watching works are summarized as below.

Marine Mammal Exclusion Zone for continuous MMO monitoring

A monitored exclusion zone of 250m radius from silt curtain or from the boundary of a work area should be implemented under the following situations (where applicable, Marine Mammal Watching Plan shall be conducted at the meantime):

1. 30 minutes before commencement of and during silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27); or

2. During implementation of Marine Mammal Exclusion Zone plan with 3 or more construction vessels requiring MMOs duty operating simultaneously in close proximity.

Marine Mammal Exclusion Zone for non-continuous MMO monitoring at marine access opening

For the construction activities requiring non-continuous MMO monitoring (i.e. opening of floating type silt curtain at marine access for reclamation works), MMO(s) will be arranged for:

1. 30 minutes before the commencement of installation / re-installation / relocation works of floating type silt curtain at marine access;

2. MMEZ monitoring during installation / re-installation / relocation of floating types silt curtain when opening and closing at marine access area; and

3. After the enclosure of floating type silt curtain at marine access area for reclamation works to implement visual inspection as detailed in Marine Mammal Watching Plan.

The marine mammal exclusion zone (MMEZ) will be carried out in order to avoid the accidental entrance and entrapment of marine mammals within the silt curtains or works area and minimize underwater acoustic disturbance, so as for precautionary purpose for DCM works. If a marine mammal is noted within the exclusion zone, all marine works should stop immediately and remain idle for 30 minutes, or until the exclusion zone is free from marine mammals. The experienced marine mammal observer should be well trained to detect marine mammals. Binoculars should be used to search the exclusion zone from an elevated platform with unobstructed visibility. The marine mammal observer(s) shall be independent of the construction contractor and shall form part of the Environmental Team and have the power to call-off construction activities.

In addition, as marine mammals cannot be effectively monitored within the proposed monitored exclusion zone at night, or during adverse weather conditions (i.e. Beaufort 5 or above, visibility of 300 meters or below), marine works requiring the exclusion zone monitoring, should be avoided under weather conditions with low visibility as much as possible. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision devise will be used. For the marine mammal monitoring during adverse weather, the MMO shall confirm the visibility of lookout point for effective implementation of the exclusion zone monitoring, whilst contractor shall confirm safety of MMO and practicability of deployment of silt curtain, otherwise marine works requiring the exclusion zone monitoring shall be ceased.

Upon the completion of silt curtain installation / re-installation / relocation, the marine works would be conducted within an enclosed environment within the silt curtain. Subsequently, Visual Inspection of the Waters Surrounded by Silt Curtains (Section 6.2) and Regular Inspection of Deployed Silt Curtain inspection (Section 6.3) under Marine Mammal Watching Plan would be implemented (where applicable, Marine Mammal Exclusion Zone shall be conducted at the meantime).

As per EP requirement from Clause 2.13 of the VEP, a Marine Mammal Watching Plan has been prepared and submitted separately to EPD, where the plan has included details of marine mammal watching actions such as regular inspection of silt curtains and visual inspection of the waters surrounded by the curtains. All measures recommended in the Marine Mammal Watching Plan shall be fully and properly implemented for the Project.

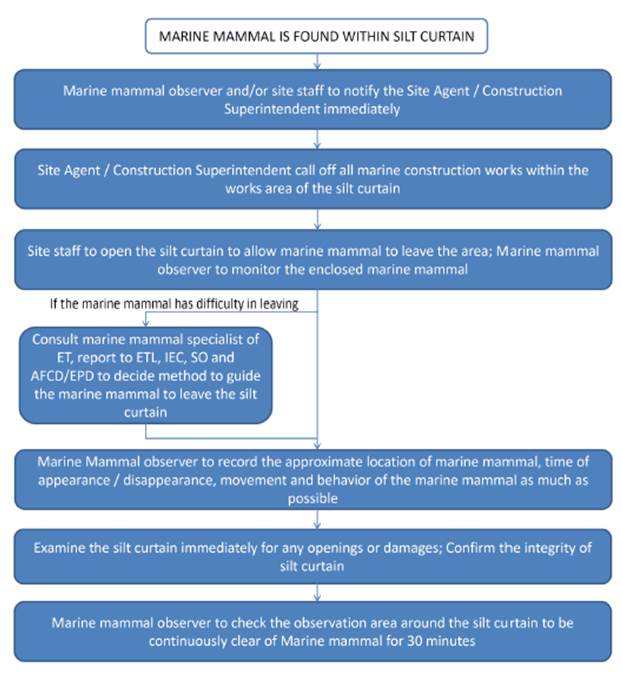

Special attention would be paid to Phase 2 (reclamation) where the floating type silt curtain would be opened occasionally for vessel access, leaving a temporary opening. An action plan has been devised to cope with any unpredicted incidents such as the case when marine mammals are found within the waters surrounded by the silt curtains as below Figure 6.

Figure 6: Response Procedures for Occurrence of Marine Mammal within Silt Curtain

6.2 Visual Inspection of the Waters Surrounded by Silt Curtains

Detailed marine mammal watching works shall refer to the approved Marine Mammal Watching Plan under FEP 01 /429/2012/A. Key components of visual inspection of the waters surrounded by silt curtains are summarized as below.

Two shifts of marine mammal observer team will be arranged for this Contract. Each shift of MMO team will be responsible for maximum 12 hours of monitoring work per day. At least two MMO(s) would be assigned as one team to work in shift to avoid / minimize fatigue of observers.

Visual inspection will be conducted by a trained MMO with naked eyes and the aid of binoculars to check for any presence of marine mammal inside the works area surrounded by silt curtains prior to commencement of works on each day. The models of the proposed marine binoculars to be used are Marine Binoculars Steiner Navigator 7X50C with Compass and Bushnell 7x50 Marine Binocular with Compass. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision device (NVD) will be used. The proposed model of NVD are from ATN, model PS15-CGTI Night Vision Goggles with 3x lens or equivalent which had proved practicable for night-time monitoring. In the event of marine mammal being sighted, the trained MMO(s) will notify the construction superintendent immediately for response actions as stated in Figure 6 and communicate with relevant parties to stop and then resume work after the discovered marine mammal leaves.

For the re-deployment of the localized silt curtains (frame-type, cage-type or enclosed floating-type silt curtains), MMO will conduct visual inspection to confirm that there is no presence of marine mammal within the localized silt curtains (frame-type, cage-type or enclosed floating-type silt curtains). Visual inspection will be conducted every an hour by MMO for confirming that there is no any marine mammal observed in the surrounding area of the deployed silt curtain during re-deployment of localized silt curtains (frame-type, cage-type or enclosed floating-type silt curtains).

In case there is any marine mammal being found, the MMO(s) should carry out the response actions as stated Figure 6 and communicate with relevant parties to stop and then resume work after the discovered marine mammal leaves.

6.3 Regular Inspection of Deployed Silt Curtains

Detailed marine mammal watching works shall refer to the approved Marine Mammal Watching Plan under FEP 01 /429/2012/A. Key components of regular inspection of deployed silt curtains are summarized as below.

Before commencement of dredging / sand blanket laying / DCM work at each designated area, a trained MMO shall check whether silt curtains are ready, well prepared and operated without any obvious damage. Also, the MMO shall confirm the presence of the relevant frontline staff of the main contractor or its sub-contractors and engineers on board to ensure the effective communication, coordination and implementation of the response plan in relation to any incidents involving marine mammals within the waters surrounded by the deployed silt curtains and the work areas.

During the operation, the inspection will be conducted daily. The MMO(s) will walk along the edge of the barge along the cage type silt curtain or proper location without obstacles where appropriate to inspect the cage type silt curtain with naked eyes, the MMO(s) will check that the cage type silt curtains are maintained in the correct positions with no obvious defects / entanglement and there is no observable muddy water passing through the cage type silt curtain. Any floating refuse trapped by the silt curtain shall be removed as part of the regular inspection. For inspection at night time, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition.

6.4 Regular Inspection of Floating Type Silt Curtain during Opening of Vessel Access

Detailed marine mammal watching works shall refer to the approved Marine Mammal Watching Plan under FEP 01 /429/2012/A. Key components of regular inspection of floating type silt curtain during opening of vessel access are summarized as below.

One trained MMO shall be on site to perform non-continuous MMO monitoring. Each shift of MMO will be responsible for maximum 12 hours of monitoring work per day and two shifts of MMO shall be arranged at the duty vessel to perform non-continuous MMO monitoring per day.

For the opening of access area of the floating type silt curtain in the reclamation area, MMO will conduct visual inspection to check for any presence of marine mammal near the opening of access areas surrounded by the floating type silt curtain every 30 minutes until the floating type silt curtain was enclosed. If the floating type silt curtains are enclosed during the reclamation work, MMO will conduct visual inspection to check for any presence of marine mammal inside the area surrounded by the floating type silt curtain daily. The duration will be subject to various conditions, e.g. weather or angle of observation. The works can only commence after confirming that the surrounding waters of the floating type silt curtains have not contain any marine mammal. Thereafter, frontline staff, i.e. foremen, site agent, superintendents and engineers will assist our MMO in implementing the plan from the active work fronts within the waters surrounded by the silt curtains throughout the work period. The MMO will conduct visual inspection daily to observe the presence of any marine mammal around the floating type silt curtains or being trapped by the localized silt curtains. The MMOs will also check if the floating type silt curtains are in correct positions.

The model of the proposed marine binoculars to be used is Marine Binoculars Steiner Navigator 7X50C with Compass and Bushnell 7x50 Marine Binoculars with Compass. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision device (NVD) will be used. The proposed model of NVD are from ATN, model PS15-CGTI Night Vision Goggles with 3x lens or equivalent which had proved practicable for night-time monitoring. In the event of marine mammal being sighted, the trained MMO(s) will notify the construction superintendent immediately for response actions as stated in Figure 6 and communicate with relevant parties to stop and then resume work after the discovered marine mammal leaves.

7 SILT CURTAIN REMOVAL / REPOSITIONING

Prior to removal of silt curtains, all marine works for which the silt curtains are deployed shall be stopped and visual inspection of the water quality within the area protected by silt curtains shall be conducted to confirm no sediment plume remaining within the works area before commencing silt curtain removal.

7.1 Floating Silt Curtains

Floating silt curtains shall be removed by detaching the chain connecting the silt curtain to the anchors, before rolling up and lifting the silt curtains and marker buoys / lights onto derrick / crane boats. Care should be taken to protect the silt curtain skirt from damage as it is dragged from the water. The remaining anchors shall be individually connected to the crane by divers and carefully lifted off the seabed for recovery onto the boats to minimize disturbance to the seabed.

During the re-positioning / re-deployment process of floating type silt curtains, in order to avoid the accidental entrance and entrapment of marine mammals within the silt curtains, a monitored exclusion zone of 250m radius from silt curtain should be implemented. The exclusion zone should be closely monitored by an experienced marine mammal observer (MMO) for at least 30 minutes before the start of re-positioning / re-deployment process. If a marine mammal is noted within the exclusion zone, all marine works should stop immediately and remain idle for 30 minutes, or until the exclusion zone is free from marine mammals. The experienced marine mammal observer should be well trained to detect marine mammals. Binoculars should be used to search the exclusion zone from an elevated platform with unobstructed visibility. The marine mammal observer(s) shall be independent of the KSZHJV and shall form part of the Environmental Team and have the power to call-off construction activities.

In order to avoid the entrance of marine mammals into the works area through the opening at silt curtains for vessel access, and the subsequent potential impacts including increase in stress level in marine mammals due to underwater noise and chance of collision with working vessels, the openings for vessel access at the silt curtains should be restricted to about 50m to minimize the risk of accidental entrance by marine mammal. The silt curtain installed in the vicinity of coral colonies is mainly served to reduce the impact of suspended solids generated from construction activities to the adjacent coral colonies. The location of installation of floating type silt curtain is attached in Appendix E.

In addition, as marine mammals cannot be effectively monitored within the proposed monitored exclusion zone at night, or during adverse weather conditions (i.e. Beaufort 5 or above, visibility of 300 meters or below), marine works requiring the exclusion zone monitoring, should be avoided under weather conditions with low visibility as much as possible. For the night-time marine mammal monitoring, spotlight will be used to provide sufficient brightness to assist the inspection in dark condition. In case of inadequate of brightness, night vision device will be used. For the marine mammal monitoring during adverse weather, the KSZHJV shall also confirm the visibility of lookout point for effective implementation of the exclusion zone monitoring, safety of MMO(s) and practicability of deployment of silt curtain, otherwise marine works requiring the exclusion zone monitoring shall be ceased.

7.2 Cage Type Silt Curtains

For cage type silt curtains, the silt curtains shall be rolled up and either securely wrapped to the top of the frame or detached from the frame completely before the cage frame is lifted and removed or re-positioned as required. Re-installation where required, shall follow the procedures specified in Section 5.

8 IMPLEMENTATION SCHEDULE

The implementation schedule as tabulated in Table 8.1 summarizes the recommended mitigation measures, the implementation parties and timing to take action while implementing the Silt Curtain Deployment Plan.

Table 8.1 Implementation Schedule

|

EIA Ref. |

Supporting Document of VEP Ref. |

Supporting Document for Reviewing Dredging Rate and Filling Rate (Rev. E) Ref. |

Current Plan Ref. |

Environmental Protection Measures / Mitigation Measures |

Location (Breakwater (B) / Seawall (S) / Coral (C) / Reclamation Area (R) |

Works Period |

Implementation Agent |

Implementation Stages* |

|||

|

Des |

C |

O |

Dec |

||||||||

|

S5b.8.1.9 |

3.3 & 8.1.1.6 |

4.3 |

2 |

Reclamation and Construction of Breakwaters / Seawalls Ÿ The proposed dredging and reclamation should be commenced in phases. The reclamation should be started within the enclosed seawalls after the substantial completion of the seawall as mentioned in Section 2 of Silt Curtain Deployment Plan. Silt curtain should be applied around caissons during the filling of the cell to prevent the loss of fine in the filling material.

Ÿ Marine access shall be located at the western side of Artificial Island, away from the identified coral communities and will be shielded by silt curtains systems to control sediment plume dispersion.

Ÿ The silt curtain system at marine access opening should be closed as soon as the barges passes through the marine access opening in order to minimize the period of curtain opening. Filling should only be carried out behind the silt curtain when the silt curtain is completely closed.

Ÿ Deployed silt curtains should be regularly checked and maintained to ensure proper functioning.

Ÿ Frame-type silt curtains should be deployed around the dredging, Grade 200 and Grade 400 rock laying and sand blanket laying operations.

Ÿ Silt curtains should be employed to enclose DCM field trial and any full scale DCM work to minimize the potential impacts on water aspect.

Ÿ Two Double layers silt curtain should be installed to embrace the coral colonies in the indirect impact site.

Ÿ As a temporary measure, one double layer silt curtain should be installed at the eastern side of Artificial Island after substantial completion of installation of block work seawall and Caisson at Seawall A and B as stated in Section 2 and Figure 1 of Appendix E.

|

B, S, R

S, R

S, R

B, S, C, R

B, S, R

B, S

C

S, R |

During dredging, reclamation and infilling of Caissons.

From upon completion of block work seawall (S_CH0 and S_CH310) and Caissons (SB_CH250 and SB_CH580 at Seawall A, Q_CH0 and CH388 at Seawall B) to completion of installation of Caissons at marine access.

From upon completion of block work seawall (S_CH0 and S_CH310) and Caissons (SB_CH250 and SB_CH580 at Seawall A, Q_CH0 and CH388 at Seawall B) to completion of installation of Caissons at marine access.

Throughout the marine works construction period

During dredging and, Grade 200 and Grade 400 rock laying, sand blanket laying

During DCM works

For construction activities that can affect the fine content of marine water such as sand blanket laying, Grade 200 and Grade 400 rock laying, dredging works, filling work below +2.5mPD at the reclamation area prior to the complete installation of caissons at marine access and operating of deep cement mixing.

From upon completion of block work seawall (S_CH0 and S_CH310) and Caissons (SB_CH250 and SB_CH580 at Seawall A, Q_CH0 and CH388 at Seawall B) to completion of seawall construction. |

KSZHJV |

|

√ |

|

|

|

7b.8.3.20 7b.8.3.24 |

4.3.3 |

|

6.1 - 6.4 |

Monitored exclusion zones For Continuous MMO monitoring Ÿ A monitored exclusion zone of 250m radius from silt curtain or from the boundary of a work area should be implemented under the following situations (where applicable, Marine Mammal Watching Plan shall be conducted at the meantime): 1. 30 minutes before commencement of and during silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27); or 2. During implementation of MMEZ cluster plan with multiple construction vessels requiring MMOs duty operating simultaneously in close proximity.

For non-continuous MMO monitoring at marine access opening Ÿ A monitored exclusion zone of 250m radius from silt curtain installed at marine access opening: 1. 30 minutes before commencement of installation / re-installation / relocation works of floating type silt curtain at marine access; 2. MMEZ monitoring during installation / re-installation / relocation of floating types silt curtain when opening and closing at marine access area; and 3. After the enclosure of floating type silt curtain at marine access area for reclamation works to implement visual inspection as detailed in Marine Mammal Watching Plan.

Ÿ The marine mammal exclusion zone (MMEZ) will be carried out in order to avoid the accidental entrance and entrapment of marine mammals within the silt curtains or works area and minimize underwater acoustic disturbance, so as for precautionary purpose for DCM works. If a marine mammal is noted within the exclusion zone, all marine works should stop immediately and remain idle for 30 minutes, or until the exclusion zone is free from marine mammals. The experienced marine mammal observer should be well trained to detect marine mammals. Binoculars should be used to search the exclusion zone form an elevated platform with unobstructed visibility. The marine mammal observer(s) shall be independent of the construction contractor and shall form part of the Environmental Team and have the power to call-off construction activities.

Ÿ In addition, as marine mammals cannot be effectively monitored within the proposed monitored exclusion zone at night, or during adverse weather conditions (i.e. Beaufort 5 or above, visibility of 300 meters or below), marine works should be avoided under weather conditions with low visibility as much as possible.

Ÿ Marine Mammal Exclusion Zone (MMEZ) Plan shall be properly implemented.

Marine mammal watching plan Ÿ Upon the completion of the installation / re-installation / relocation of floating type silt curtain, the marine works would be conducted within a full enclosed environment within the silt curtain. Subsequently, Visual Inspection of the Waters Surrounded by Silt Curtains (Section 2.1, MMWP) and Regular Inspection of Deployed Silt Curtain (Section 2.2, MMWP) would be implemented (where applicable, Marine Mammal Exclusion Zone shall be conducted at the meantime).

Ÿ All measures recommended in the Marine Mammal Watching Plan shall be fully and properly implemented for the Project.

Ÿ Special attention should be paid to Phase 2 (reclamation) where the floating type silt curtain would be opened occasionally for vessel access, leaving a temporary 50m opening. An action plan devised in the Marine Mammal Watching Plan shall be properly implemented to cope with any unpredicted incidents such as the case when marine mammals are found within the waters surrounded by the silt curtains.

Small openings at silt curtains Ÿ In order to avoid the entrance of marine mammals into the works area through the opening at silt curtains for vessel access, and the subsequent potential impacts including increase in stress level in marine mammals due to underwater noise and chance of collision with working vessels, the openings for vessel access at the silt curtains should be restricted to be from 50m 100m to minimize the risk of accidental entrance by marine mammal. |

B, S, C

R

B, S, C, R

B, S, C, R

B, S, C, R

B, S, R

B, S, R

S, R

S, R |

Throughout the whole marine works construction period when carrying out silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27) and during implementation of MMEZ cluster plan with multiple construction vessels requiring MMOs duty operating simultaneously in close proximity.

Throughout the whole marine works reclamation period prior to completion of installation of caissons at marine access opening.

Throughout the whole marine works construction period when carrying out silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27) and during implementation of MMEZ cluster plan with multiple construction vessels requiring MMOs duty operating simultaneously in close proximity.

Throughout the whole marine works construction period when carrying out silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27) and during implementation of MMEZ cluster plan with multiple construction vessels requiring MMOs duty operating simultaneously in close proximity.

Throughout the whole marine works construction period when carrying out silt curtain installation / re-installation / relocation, deep cement mixing injection works or noisy construction works (as stipulated in FEP Clause 2.27) and during implementation of MMEZ cluster plan with multiple construction vessels requiring MMOs duty operating simultaneously in close proximity.

Throughout the whole marine works construction period for deployed silt curtains formed enclosed environment and to carry out marine works inside an enclosed environment.

Throughout the whole marine works construction period for deployed silt curtains formed enclosed environment and to carry out marine works inside an enclosed environment.

Throughout the whole marine works construction period.

From upon completion of block work seawall (S_CH0 and S_CH310) and Caissons (SB_CH250 and SB_CH580 at Seawall A, Q_CH0 and CH388 at Seawall B) to completion of installation of Caissons at marine access.

|

KSZHJV |

|

√ |

|

|

|

7b.8.3.30 |

|

|

5.1 |

Training of staff Ÿ For the implementation of Marine Mammal Watching Plan and Marine Mammal Exclusion Zone Plan, training sessions shall be conducted for MMO by marine mammal specialist, Dr. Samuel Hung, Dr. Lindsay Porter, Ms. Julia Chan or someone with equivalent qualification, with briefing materials provided as guidelines, instructing adequate knowledge of all requirements for observing marine mammal and appropriate actions to be taken according to this plan. Competence checking by ET shall be provided at least once every 6 months to the trained MMO involved in implementation of this plan.

Ÿ As frontline staff of the main contractor or its sub-contractors, i.e. foremen, site agent, superintendents and engineers would involve in the implementation of this plan, briefings for these personnel will be provided by the trained MMO during induction trainings to get familiar with the plans for assisting on marine mammal observations within waters surrounded by silt curtains and taking necessary action according to the plans when there is marine mammal trapped by the silt curtain or appearance of marine mammal within the MMEZ. Refresh briefings will be provided to all frontline staff once every 6 months. The briefing and training records will be provided to ETL, IEC and SO for audit and record. |

|

Throughout the whole marine works construction period.

Throughout the whole marine works construction period. |

KSZHJV |

|

√ |

|

|

Note: * - Des Design; C Construction; O Operation; Dec - Decommissioning