Revision History

|

E |

Revision based on EPDÕs comment |

19 Apr 2021 |

|

D |

Revision based on EPDÕs comment |

16 Mar 2021 |

|

C |

Updated Section 1.3, 4.3, 4.4, 4.5, 6.2.1.6, 6.3.7, 6.3.8, 6.4.4.4, 11.1, Appendix 1.1, Appendix 11.1 |

01 Dec 2020 |

|

B |

Revision based on EPDÕs comment |

08 Jun 2018 |

|

A |

First Issue for Comments |

19 Mar 2018 |

|

Rev. |

Description of Modification |

Date |

TABLE OF CONTENT

1. INTRODUCTION

1.1. Purpose of the Manual

1.2. Project Description

1.3. Scope of Project

1.4. Construction Programme

1.5. Project Organization

1.6. Structure of this Manual

2. AIR QUALITY IMPACT

2.1. Introduction

2.2. Monitoring during Construction Phase

2.3. Monitoring during Operation Phase

3. NOISE IMPACT

3.1. Introduction

3.2. Noise Parameters

3.3. Baseline Monitoring

3.4. Impact Monitoring

3.5. Event and Action Plan

3.6. Mitigation Measure

4. WATER QUALITY IMPACT

4.1. Introduction

4.2. Water Quality Parameters

4.3. Monitoring Locations

4.4. Baseline Monitoring

4.5. Impact Monitoring

4.6. Efficiency of Silt Curtain at Marine Access Opening

4.7. Site Audits

4.8. Field Log

4.9. Monitoring Equipment

4.10. Laboratory Measurement / Analysis

4.11. Event and Action Plan

4.12. Mitigation Measures

4.13. Water Quality Monitoring for Deep Cement Mixing Works

5. WASTE MANAGEMENT IMPLICATIONS

5.1. Introduction

5.2. Waste Management and Control

5.3. Monitoring Requirements for Biogas Generation

5.4. Approach to Prevent Land Contamination

6. ECOLOGICAL IMPACT

6.1. Introduction

6.2. Ecological Mitigation Measures

6.3. Marine Mammal Monitoring

6.4. Coral Monitoring Programme

6.5. White-bellied Sea Eagle Monitoring Programme

6.6. Reference

7. FISHERIES IMPACT

8. HEALTH IMPACT

9. LANDSCAPE AND VISUAL IMPACT

9.1. Introduction

9.2. Mitigation Measures

9.3. Baseline Review

9.4. Construction Phase Audit

10. IMPACT ON CULTURAL HERITAGE

11. SITE ENVIRONMENTAL AUDIT & ENVIRONMENTAL COMPLAINTS

11.1. Site Inspection

11.2. Compliance with Legal and Contractual Requirements

11.3. Environmental Complaint

12. REPORTING

12.1. General

12.2. Baseline Monitoring Report

12.3. Monthly EM&A Reports

12.4. Quarterly EM&A Summary Reports

12.5. Final EM&A Review Report

12.6. Data Keeping

12.7. Interim Notifications of Environmental Quality Limit Exceedances

LIST OF TABLES

|

Table 1.1 |

Construction Programme of the IWMF at the Artificial Island near SKC |

|

Table 2.1 |

Analytical Parameters and Methodology |

|

Table 2.2 |

Odour Intensity Level |

|

Table 2.3 |

Action and Limit Levels for Odour Nuisance |

|

Table 2.4 |

Event and Action Plan for Odour Monitoring |

|

Table 3.1 |

The Locations of Construction Noise Monitoring Station |

|

Table 3.2 |

Action and Limit Levels for Construction Noise |

|

Table 3.3 |

Event/Action Plan for Construction Noise |

|

Table 4.1 |

Proposed Marine Water Quality Stations for Baseline and Impact Monitoring during Construction Phase |

|

Table 4.2 |

Proposed Marine Water Quality Stations for Baseline and Impact Monitoring during Operational Phase |

|

Table 4.3 |

Proposed Marine Water Quality Monitoring Frequency and Parameters for Construction Phase Impact Monitoring |

|

Table 4.4 |

Proposed Marine Water Quality Monitoring Frequency and Parameters for Operational Phase Impact Monitoring |

|

Table 4.5 |

Event and Action Plan for Marine Water Quality |

|

Table 4.6 |

Action and Limit Levels for Marine Water Quality |

|

Table 4.7 |

Event and Action Plan for Construction Phase Marine Water Quality |

|

Table 4.8 |

Event and Action Plan for Operation Phase Marine Water Quality |

|

Table 6.1 |

Action and Limit Levels for Post-Translocation Coral Monitoring |

|

Table 6.2 |

Event and Action Plan for Post-Translocation Monitoring |

|

Table 6.3 |

Action and Limit Levels for Coral Monitoring at Construction Phase |

|

Table 6.4 |

Event and Action Plan for Coral Monitoring at Construction Phase |

|

Table 6.5 |

Event and Action Plan for WBSE Monitoring during Construction Phase |

|

Table 6.6 |

Event and Action Plan for WBSE Monitoring during Operation Phase |

|

Table 9.1 |

Recommended Landscape and Visual Mitigation Measures |

LIST OF FIGURES

|

Figure 1.1 |

Location Plan of the IWMF at the Artificial Island near Shek Kwu Chau |

|

Figure 1.2 |

General Layout of the IWMF at the Artificial Island near Shek Kwu Chau |

|

Figure 1.3 |

Project Organization - EM&A Programme for Construction Phase |

|

Figure 1.4 |

Project Organization - EM&A Programme for Operation Phase |

|

Figure 3.1 |

The Locations of Construction Noise Monitoring Stations |

|

Figure 4.1 |

Locations of Water Quality Monitoring Stations for Construction Phase Impact Monitoring |

|

Figure 4.2 |

Locations of Water Quality Monitoring Stations for Operation Phase Impact Monitoring |

|

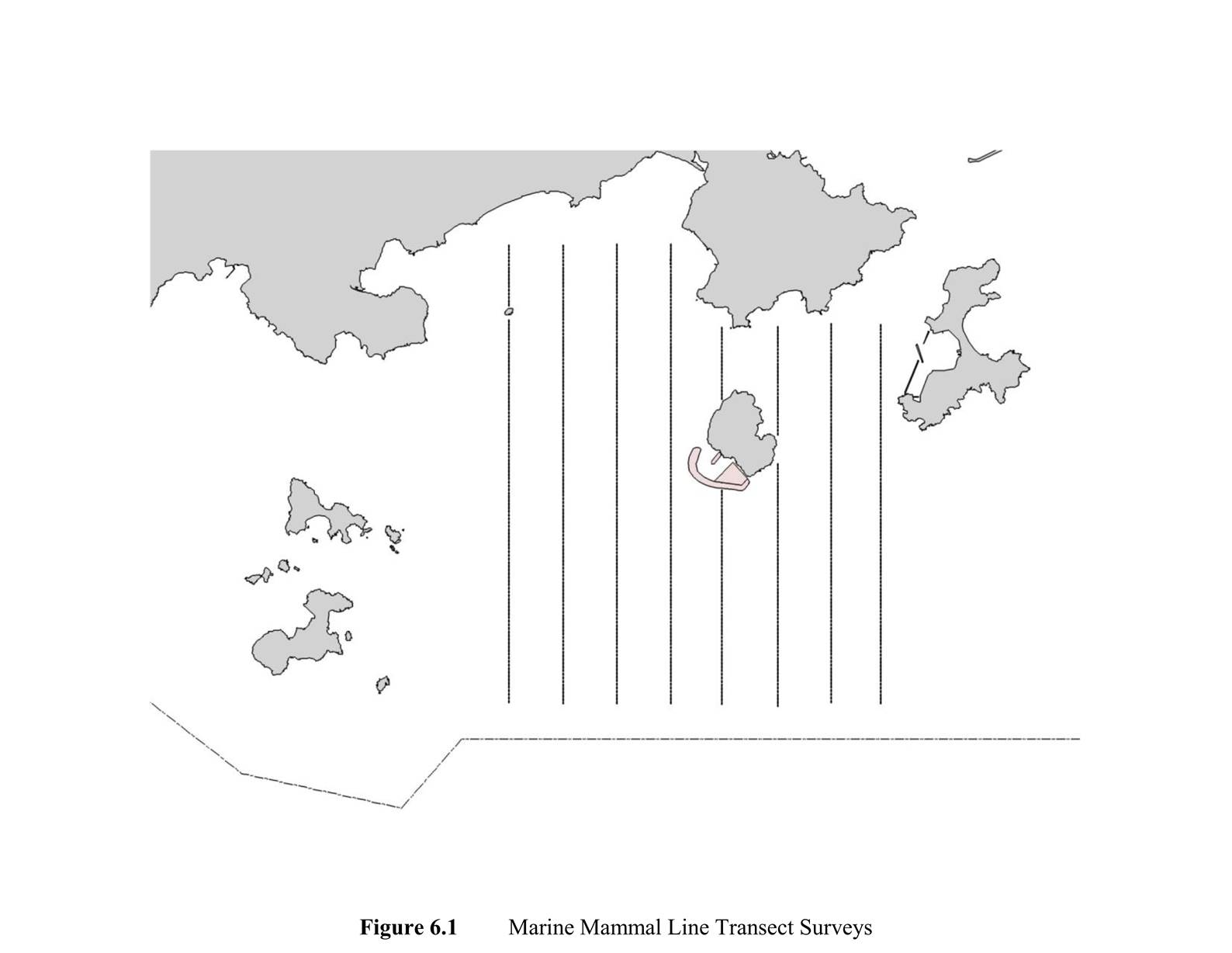

Figure 6.1 |

Marine Mammal Line Transect Surveys |

|

Figure 6.2 |

Indicative Travel Route for the IWMF Vessels |

|

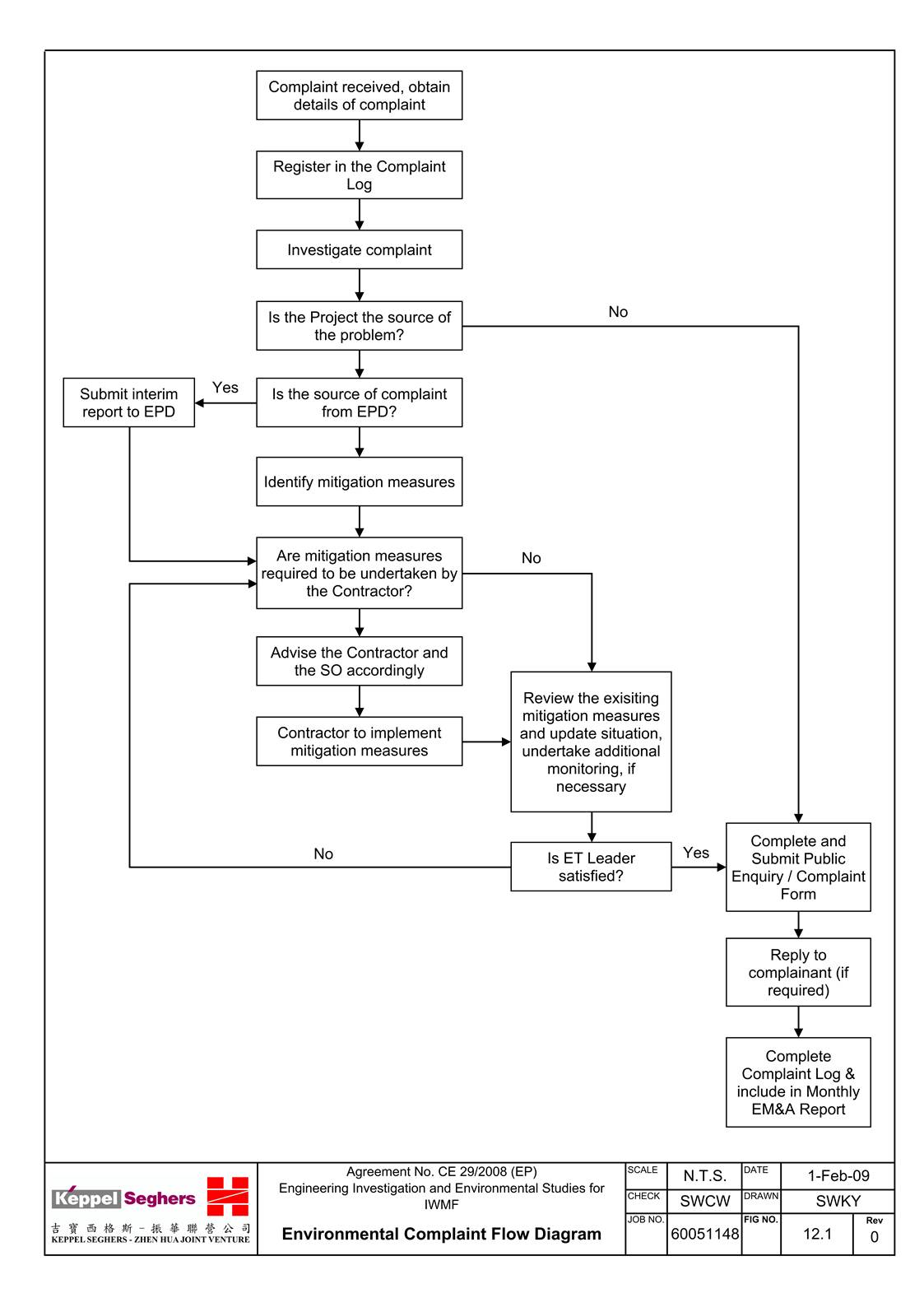

Figure 12.1 |

Environmental Complaint Flow Diagram |

LIST OF APPENICES

|

Appendix 1.1 |

|

|

Appendix 3.1 |

|

|

Appendix 4.1 |

|

|

Appendix 11.1 |

|

|

Appendix 12.1 |

Incident Report on Action Level or Limit Level Non-compliance |

1. INTRODUCTION

1.1. Purpose of the Manual

1.1.1. The purpose of this Environmental Monitoring and Audit (EM&A) Manual (hereafter referred to ÒManualÓ) is to guide the setting up of an EM&A programme to ensure compliance with the recommendations of the Environmental Impact Assessment (EIA) Study and to assess the effectiveness of the recommended mitigation measures as well as to identify any further need for additional mitigation measures or remedial action. This Manual outlines the monitoring and audit programme for the construction and operation phase of the Integrated Waste Management Facilities (IWMF). It aims to provide systematic procedures for monitoring, auditing and minimizing environmental impacts associated with the construction works and operational activities of the IWMF.

1.1.2. Hong Kong environmental regulations and the Hong Kong Planning Standards and Guidelines have served as environmental standards and guidelines in the preparation of this Manual. In addition, the EM&A Manual has been prepared in accordance with the requirements stipulated in Annex 21 of the Technical Memorandum on the EIA Process (EIAO-TM).

1.1.3. This Manual contains the following information:

á responsibilities of the Contractor, the Supervising OfficerÕs Representative (SO), the Independent Consultants (IC), Environmental Team (ET), the Independent Environmental Checker (IEC), EIAO Authority of Environmental Protection Department (EPD) with respect to the environmental monitoring and audit requirements during the course of the Project;

á project organization for the Project;

á the basis for and description of the broad approach underlying the EM&A programme;

á requirements with respect to the construction programme schedule and the necessary environmental monitoring and audit programme to track the varying environmental impacts;

á details of the methodologies to be adopted, including all field laboratories and analytical procedures and details on quality assurance and quality control programme;

á definition of action and limit levels;

á establishment of event and action plans;

á requirements for reviewing pollution sources and working procedures required in the event of non-compliance with the environmental criteria and complaints;

á requirements for presentation of environmental monitoring and audit data and appropriate reporting procedures; and

á requirements for review of EIA predictions and the effectiveness of the mitigation measures / environmental management systems and the EM&A programme.

1.1.4. For the purpose of this manual, the ET leader, who shall be responsible for and in charge of the ET, shall refer to the person delegated the role of executing the EM&A requirements.

1.2. Project Description

1.2.1. Introduction

The Project is to construct and operate a modern IWMF for managing municipal solid waste (MSW) under a design-build-operate (DBO) contract arrangement. The IWMF comprises: (a) an advanced thermal incineration plant with design capacity of 3,000 tonnes per day (tpd) and (b) a mechanical sorting and recycling plant with design capacity of 200 tpd. The non-recyclables sorted from the mechanical plant will be sent to the thermal incineration plant for further treatment. Under any conditions, the total MSW feeding to the thermal incineration plant and the mechanical plant will not exceed 3,000 tpd.

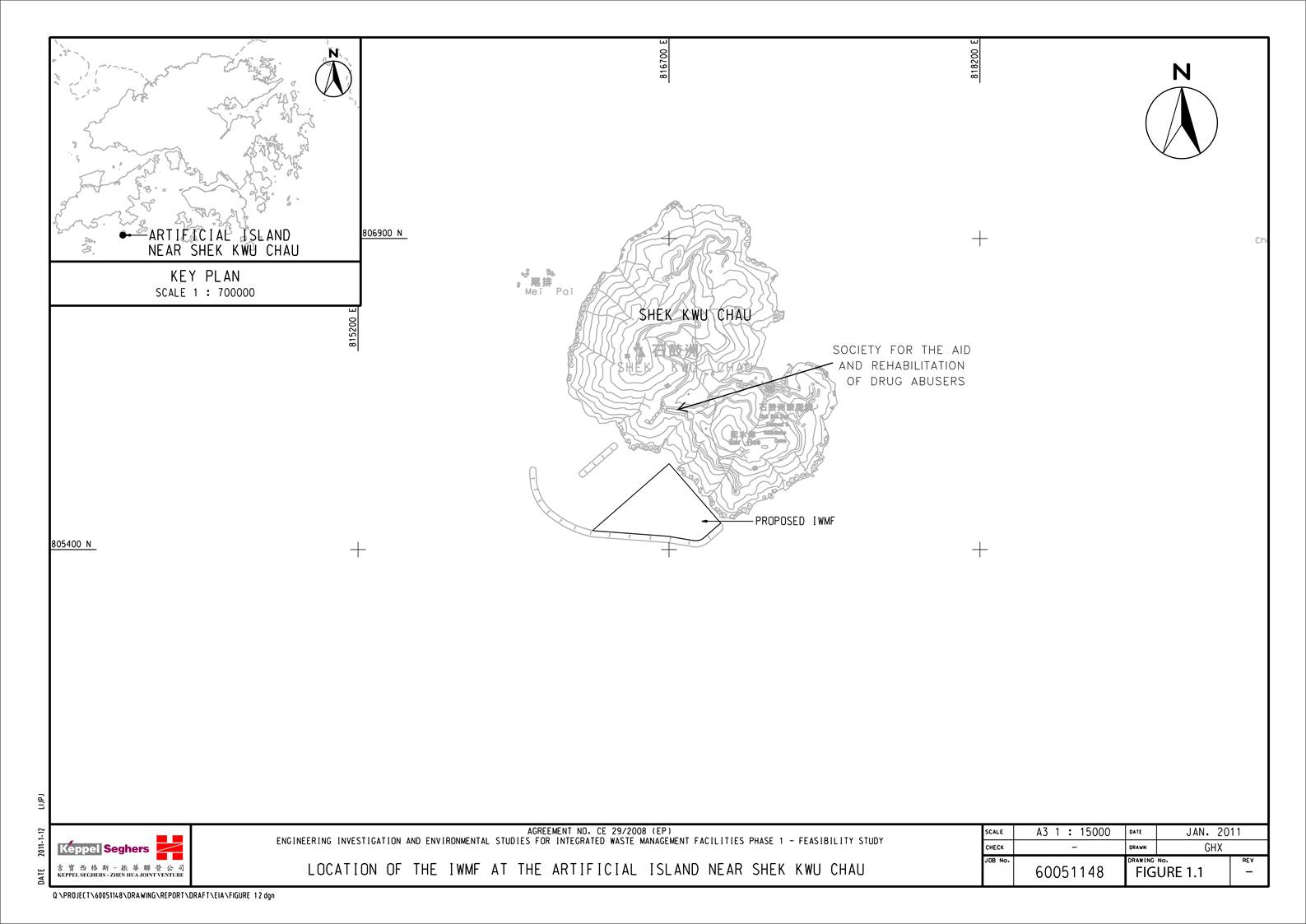

The project site has been decided for the development of the IWMF in an artificial island near Shek Kwu Chau (SKC) and the location is shown in Figure 1.1.

1.3.1. The infrastructure for this Project would comprise an incineration plant, a mechanical sorting and recycling plant, and ancillary & supporting facilities. The details of these components as listed below:

Incineration Plant

á MSW receiving, storage and feeding system

á Moving grate incineration furnaces

á Waste heat recovery and power generation system

á Boiler feedwater treatment system

á Flue gas treatment system

á Flue gas discharge system with stack

á Ash storage and handling system

á Reagent reception and storage system

á Odour control system

á Process control and monitoring system

Mechanical Treatment (MT) Plant

á MSW receiving, storage and feeding system

á Mechanical treatment system including shredding and sorting facilities

á Products and by-products storage and handling system

á Odour control system

á Process control and monitoring system

Ancillary & Supporting Facilities

á Weighbridge

á Site security

á Administration building / environmental education centre

á Vehicle washing facilities

á Maintenance workshop

á Fuel storage tanks

á Water treatment plant

á Wastewater treatment plant

á Electricity supply and export system

á Utilities

á Berthing area for marine vessels and storage of refuse containers

1.3.2. Design-Build-Operate (DBO) contract arrangement would be adopted for the Project and the operation period would be 15 years. Under this contract arrangement, a DBO contractor would be engaged to conduct the detailed design, construction and operation of the IWMF.

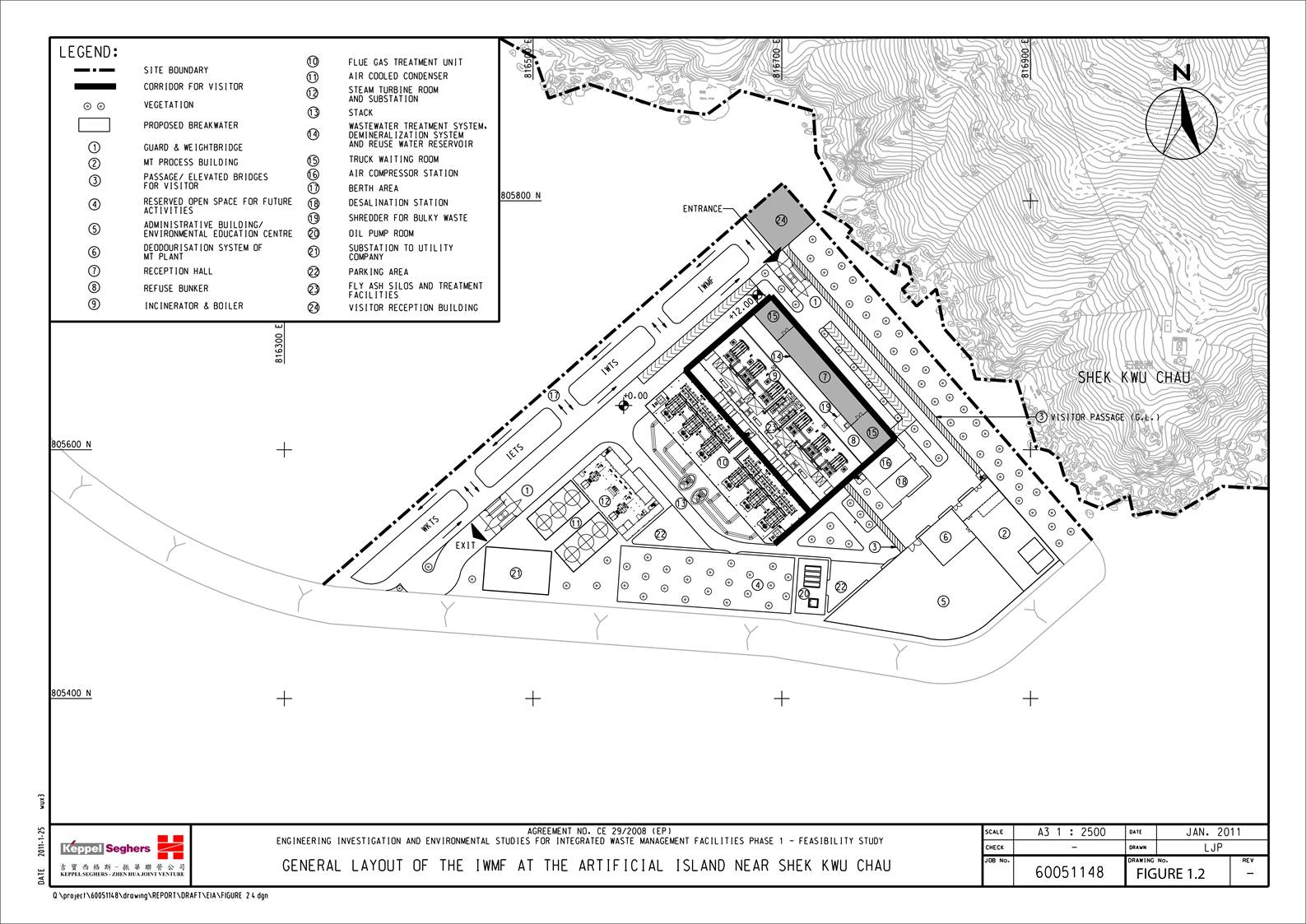

1.3.3. The preliminary layouts showing the IWMF facilities at the artificial island near SKC are presented in Figure 1.2.

Construction of the IWMF

1.3.4. The scope of works in construction and operation phase of the Project for the Artificial Island near Shek Kwu Chau is described as below:

1.3.5. Reclamation will be needed to form about 11.8 hectares of land for the IWMF. Due to occasionally rough sea condition in the vicinity of the artificial island near SKC, breakwater will be provided to ensure safe loading and unloading operation at the berth area.

1.3.6. The reclamation will be formed with filling materials supported on the insitu marine deposits with suitable geotechnical ground treatment (such as surcharge loading, installation of vertical band drains, etc.) at a finished ground level of about +5mPD high. Seawalls will be constructed to confine the reclamation area and breakwaters will be provided to protect the water basin. To minimize dredging and filling activities and the associated environmental impacts, vertical cellular structure consisting of circular cells instead of sloping gravity structure is proposed to be adopted for the construction of the seawalls and breakwaters. The cellular breakwater protecting the reclamation area and the water basin would be about +9mPD high for resisting waves with significant heights.

1.3.7. The berth area, which will be extended from the seawall at the northwest side of the reclaimed area, will be formed by a piled deck structure with precast slab. Tubular piles are proposed to form the foundation of the berth. Non-percussive bore piling method would be adopted for the installation of tubular piles.

1.3.8. The construction of the IWMF will mainly include the following stages:-

á Construction of precast concrete cassion surrounding the reclamation area;

á Site filling for reclamation;

á Surcharge loading for reclamation area;

á Construction of breakwater;

á Pilling for berth area;

á Site drainage;

á Foundation (spread footing);

á Civil and building works;

á Mechanical & electrical plant installation;

á Roads, utilities, services and landscaping; and

á Ancillary instrumentation and control works.

Operation of the IWMF

1.3.9. The IWMF will be operated on a 24-hour basis daily, while the reception of MSW would be limited from 8 am to 8 pm.

1.3.10. About 3,000 tpd MSW would be delivered by marine vessels from the existing refuse transfer stations, including Island East Transfer Station, Island West Transfer Station and West Kowloon Transfer Station.

1.4. Construction Programme

1.4.1. The project specific construction programmes for the artificial island near SKC are shown in Table 1.1 and illustrated in Appendix 1.1.

Table 1.1 Construction Programme of IWMF at the Artificial Island near SKC

|

Description |

Date |

|

Award of Contract |

22 Nov 2017 |

|

Phase I Ð Construction of Perimeter Seawalls |

10 Jan 2018 Ð 21 Sep 2018 |

|

Seawall at DCM Area |

29 Jun 2018 Ð 21 Sep 2019 |

|

Seawall at Dredging Area |

22 Aug 2018 Ð 09 Sep 2019 |

|

Phase II Ð Reclamation, Breakwater and Berth Construction |

22 Sep 2019 Ð 27 Jun 2021 |

|

Reclamation |

22 Sep 2019 Ð 27 Jun 2021 |

|

Breakwater |

22 Sep 2019 Ð 07 Mar 2021 |

|

Foundation Works |

12 Apr 2021 Ð 13 May 2022 |

|

Superstructure Works |

12 Aug 2021 Ð 12 Jan 2023 |

|

Architectural Builders Works and Finishes |

07 Nov 2021 Ð 09 Sep 2023 |

|

Building Services Installation |

20 Feb 2022 Ð 20 Oct 2023 |

|

Process Equipment Installation |

27 Jan 2022 Ð 04 Nov 2023 |

|

Landscape, External Road and Drains Works |

07 Nov 2021 Ð 26 Apr 2024 |

|

Testing and Commissioning |

04 Jan 2023 Ð 27 Jul 2024 |

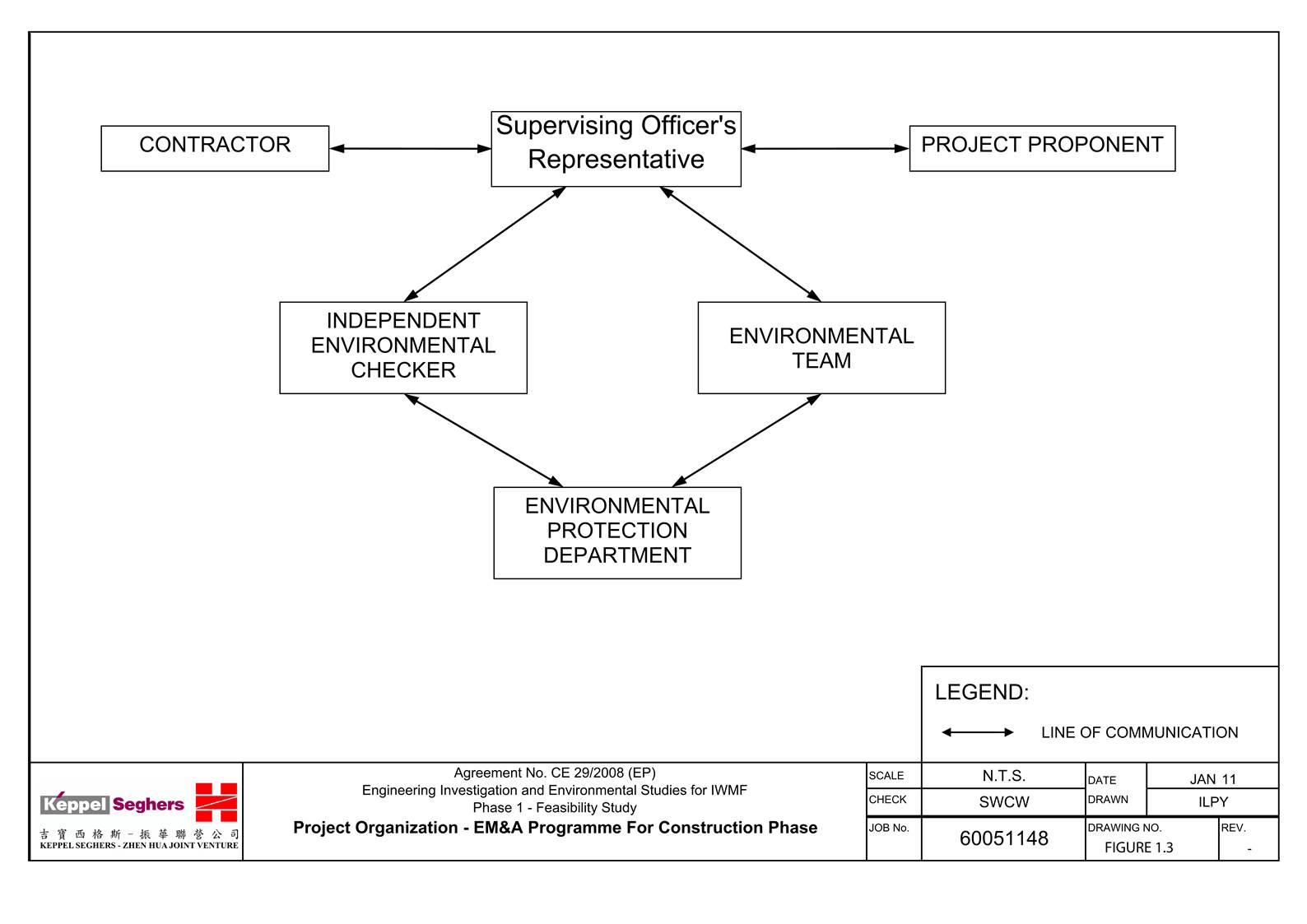

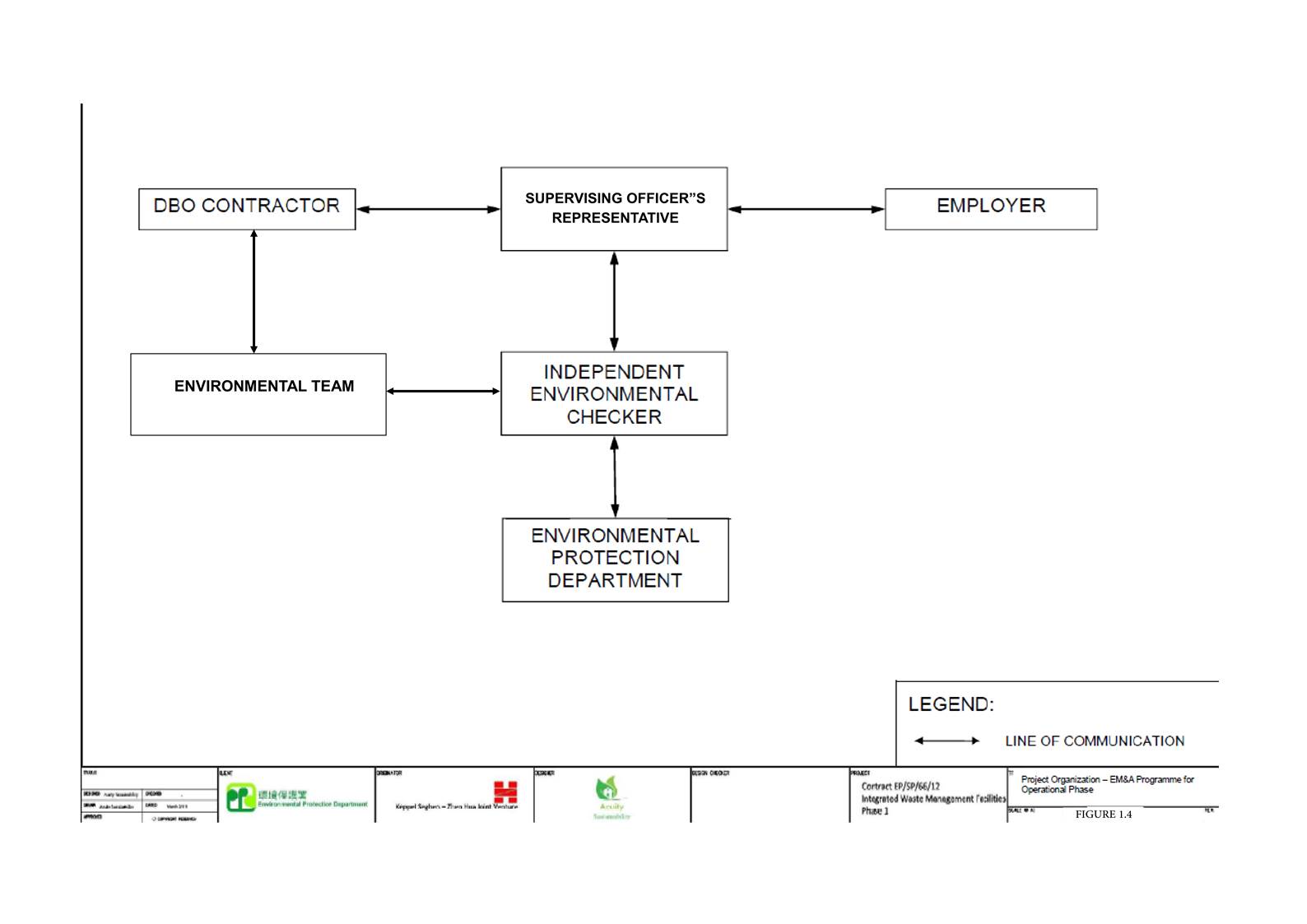

The roles and responsibilities of the various parties involved in the construction and operation phases of the EM&A process and the implementation of the EM&A programme are outlined below. The proposed project organization and lines of communication during construction and operation phase with respect to environmental protection works are shown in Figure 1.3 and Figure 1.4 respectively.

1.5.2. Construction Phase

Supervising OfficerÕs Representative

1.5.2.1 The term ÒSupervising OfficeÕs Representative (SO)Ó refers to the organization responsible for overseeing the construction works of the Project undertaken by the Contractor, and for ensuring that they are undertaken by the Contractor in accordance with the specification and contractual requirements. The responsibilities of the SO include the followings:-

á Monitor the ContractorÕs compliance with contract specifications, including the implementation and operation of the environmental mitigation measures and ensure their effectiveness, and other aspects of the EM&A programme;

á Monitor the ContractorÕs, the ETÕs and the IECÕs compliance and ensure that the requirements in the Environmental Permit (EP) and EM&A Manual are fully complied with;

á Provide assistance to the ET as necessary in the implementation of the EM&A programme;

á Participate in joint site inspection undertaken by the ET and the IEC;

á Comply with the agreed Event / Action Plan in the event of any exceedance; and

á Adhere to the procedures for carrying out complaint investigation.

Contractor

1.5.2.2 The term ÒContractorÓ should be taken to mean all construction contractors and sub-contractors, working on site at any one time. Besides reporting to the SO, the Contractor should also be responsible for the following tasks:

á Work within the scope of the relevant contract and other tender conditions;

á Provide assistance to the ET in carrying out monitoring;

á Participate in the site inspections undertaken by the ET as required, and undertake any corrective actions;

á Provide information / advice to the ET regarding works activities which may contribute, or be continuing to the generation of adverse environmental conditions;

á Submit proposals on mitigation measures in case of exceedances of action or limit levels in accordance with the event / action plans;

á Implement measures to reduce impact where action or limit levels are exceeded; and

á Adhere to the procedures for carrying out complaint investigation.

Independent Environmental Checker (IEC)

1.5.2.3 The Independent Environmental Checker (IEC) should not be in any way an associated body of the Contractor for the Project. The responsibilities of the IEC should include the followings:-

á Advise the SO on environmental issues related to the project, independent from the management of construction works, but empowered to audit the environmental performance of construction of the IWMF;

á Provide proactive advice to the SO and the Employer of the Project on environmental matters;

á Review and audit all aspects of the EM&A programme, including the implementation of environmental mitigation measures, submission relating to the EP and EM&A, and any other submission required under the EP and EM&A Manual;

á Review and verify the monitoring data and all submissions relating to or under the EP and EM&A Manual submitted by the ET, including but not limited to the EM&A reports;

á Monitor the implementation of the EM&A programme and the overall level of environmental performance being achieved;

á Arrange and conduct regular, at least monthly site inspections of the works during construction phase, and ad hoc inspections if significant environmental problems are identified;

á Comply with the agreed event / action plan in the event of any exceedance;

á Check and ensure the procedures for carrying out complaint investigation being followed and check the effectiveness of corrective measures;

á Feedback audit results to ET by signing off relevant EM&A proforma;

á Ensure the impact monitoring is conducted at the correct locations at the frequency identified in the EM&A Manual;

á Check that the mitigation measures are effectively implemented; and

Report the works conducted, the findings, recommendation and improvement of the site inspections, the findings, recommendation, and improvement after reviewing the ETÕs and the ContractorÕs works, and any advices to the SO and the Employer of the Project on a monthly basis.

Environmental Team

1.5.2.4 The ET shall not be in any way an associated body of the Contractor, and shall be responsible to conduct the EM&A programme. The ET should be managed by the ET Leader. The ET Leader shall be a person who has at least 7 yearsÕ experience in EM&A and have relevant professional qualifications. Suitably qualified staff should be included in the ET, and resources for the implementation of the EM&A programme should be allocated in time under the Contract, to enable fulfilment of the ProjectÕs EM&A requirements as specified in the EM&A Manual during construction of the Project. The ET shall report to the SO and the duties of ET shall include the followings:-

á Monitor and audit various environmental parameters as required in this EM&A Manual;

á Analyse the environmental monitoring and audit data and review the success of EM&A programme to cost-effectively confirm the adequacy of mitigation measures implemented and the validity of the EIA predictions and to identify any adverse environmental impacts arising;

á Carry out regular site inspection to investigate and audit the ContractorÕs site practice, equipment and work methodologies with respect to pollution control and environmental mitigation, and effect proactive action to pre-empt problems;

á Monitor compliance with conditions in the EP, environmental protection, pollution prevention and control regulations and contract specifications;

á Audit environmental monitoring data and site environmental conditions;

á Report on the environmental monitoring and audit results to EPD, the SO, the IEC and Contractor or their delegated representative;

á Recommend suitable mitigation measures to the Contractor in the case of exceedance of action or limit levels in accordance with the event and action plans;

á Liaise with the IEC on all environmental performance matters and timely submit all relevant EM&A proforma for approval by the IEC;

á Advise the Contractor on environmental improvement, awareness, enhancement matters, etc. on site;

á Adhere to the procedures for carrying out complaint investigation; and

á Timely submit the EM&A Reports to EPD.

1.5.2.5 Sufficient and suitably qualified professional and technical staff should be employed to ensure full compliance with their duties and responsibilities, as required under the EM&A programme during the construction phase of the Project.

1.5.3. Operation Phase

1.5.3.1 Under the DBO contract, the Contractor will be responsible for the operation of the IWMF. The Contractor will ensure compliance of the conditions of the Environmental Permit and continue to appoint the ET and IEC to carry out the monitoring works and audit works respectively during the operation phase in accordance to this EM&A Manual. The responsibilities of the IEC shall be the same as the construction phase.

1.5.3.2 The responsibilities of the ET during the operation phase shall include the follows:-

á Monitor various environmental parameters as required in this EM&A Manual;

á Report on the environmental monitoring results to the Contractor, the SO and the IEC;

á Analyze monitoring results collected from the monitoring works;

á Prepare monitoring reports to provide the impact evaluation results to the Contractor, the SO and the IEC; and

á Recommend suitable actions to the Contractor and SO in case of exceedance of any assessment criteria.

1.6.1. Following this introductory section, the structure of the EM&A Manual is set out below:-

á Section 2 details the requirement for impact monitoring for dust during the construction phase and for air emission from IWMF and odour during the operation phase at IWMF.

á Section 3 details the requirement for impact monitoring for construction noise at IWMF.

á Section 4 details the requirements for baseline and impact monitoring for water quality during the construction phase at IWMF respectively.

á Section 5 details the audit requirements with regard to waste management issues as well as the waste control and mitigation measures recommended in the EIA at IWMF.

á Section 6 details the requirements for monitoring and audit of the ecological impacts during the construction and operation phases at IWMF.

á Section 7 details the requirements for monitoring and audit of the fisheries impacts during the construction and operation phases at IWMF.

á Section 8 details the monitoring requirements with regard to human health risk as recommended in the EIA at IWMF.

á Section 9 details the requirements with regard to landscape and visual issues at IWMF.

á Section 10 details the requirements for monitoring and audit of the cultural heritage impact during the construction and operation phases at IWMF.

á Section 11 details the requirements on site environmental audit and the environmental complaints handling procedure.

á Section 12 details the EM&A reporting requirements

2. AIR QUALITY IMPACT

2.1.1. This section presents the requirements, methodology, equipment, criteria and protocols for the monitoring and audit of air quality impacts during the construction and operation phases of the Project.

2.1.2. The objectives of the air quality monitoring include the following:-

á to identify the extent of construction dust and operational odour impacts;

á to determine the effectiveness of mitigation measures to control dust emission from activities during construction phase and odour control measures during operation phase;

á to audit the compliance of the Contractor with regard to dust control, contract conditions and the relevant dust impact criteria;

á to recommend further mitigation measures if found to be necessary; and

á to comply with action and limit levels for air quality as defined in this Manual.

2.1.3. During the construction phase of the Project, the dust impact would be the major air quality impact. While during operation phase of the Project, stack emissions would be the key environmental issue. Apart from the stack emission, odour emission arising from the operation of the IWMF and its on-site wastewater treatment plant, the waste reception halls, the waste storage area, and the mechanical treatment plant would be another key environmental issue.

2.2. Monitoring during Construction Phase

2.2.1. With the implementation of practicable dust suppression measures stipulated in the Air Pollution Control (Construction Dust) Regulation, adverse construction dust impact at Air Sensitive Receivers (ASRs) is not expected during construction of the Project. In view of the large separation distance of the nearby ASRs from the Project Site, no dust monitoring is considered necessary. Yet, regular site environmental audits during the construction phase of the Project as described in Section 11 of this Manual should be conducted to ensure that the recommended dust suppression measures are implemented properly.

2.2.2. Mitigation measures for dust control have been recommended in the EIA Report and are listed below:-

á Use of regular watering, with complete coverage, to reduce dust emissions from exposed site surfaces and unpaved roads, particularly during dry weather;

á Use of frequent watering for particularly dusty construction areas and areas close to ASRs;

á Side enclosure and covering of any aggregate or dusty material storage piles to reduce emissions. Where this is not practicable owing to frequent usage, watering shall be applied to aggregate fines;

á Open stockpiles shall be avoided or covered. Where possible, prevent placing dusty material storage piles near ASRs;

á Tarpaulin covering of all dusty vehicle loads transported to, from and between site locations;

á Establishment and use of vehicle wheel and body washing facilities at the exit points of the site;

á Provision of wind shield and dust extraction units or similar dust mitigation measures at the loading points, and use of water sprinklers at the loading area where dust generation is likely during the loading process of loose material, particularly in dry seasons / periods;

á Imposition of speed controls for vehicles on unpaved site roads. Ten kilometres per hour is the recommended limit;

á Where possible, routing of vehicles and positioning of construction plant should be at the maximum possible distance from ASRs; and

á Instigation of an environmental auditing program to monitor the construction process in order to enforce controls and modify method of work if dusty conditions arise.

2.2.3. The Contractor shall be responsible for the design and implementation of these measures.

2.3. Monitoring during Operation Phase

2.3.1. Stack Monitoring

2.3.1.1 Monitoring of air quality parameters of concern due to stack emissions has to be conducted during operation phase of the Project in accordance with the requirements similar to those stipulated in the ÒA Guidance Note on the Best Practicable Means for Incinerators (Municipal Waste Incineration) BPM 12/1Ó.

2.3.1.2 The parameters for measurement and the analytical methods are listed in Table 2.1. It should be noted that the proposed sampling methods below are for reference only and should be subject to the approval of EPD.

Table 2.1 Analytical Parameters and Methodology

|

Parameters |

Method |

|

Dioxin and Furans |

USEPA Method 23 |

|

HCl and HF |

USEPA Method 26 A USEPA Method 13B sampling train |

|

Heavy Metals Cd, Tl, Hg, Sb, As, Pb, Cr, Co, Cu, Mn, Ni and V Ð particulate and gaseous form |

USEPA Method 29 |

|

Gaseous and vaporous organic substances |

USEPA Method 18 USEPA Method 0031 |

|

Combustion Gases |

|

|

Carbon Dioxide |

Fyrite analyser, Combustion analyser |

|

Carbon Monoxide |

Combustion Gas Analyser |

|

NOX/NO |

USEPA Reference methods USEPA Method 7 and associated methods, |

|

Oxygen |

Combustion Gas Analyser (chemical cell and paramagnetic) |

|

Sulphur dioxide and Sulphuric Acid Mist |

USEPA Method 8 |

|

Particulate |

ISO 9096, ASTM D3685-98, USEPA Method 17 |

|

Velocity and Volumetric Flow |

ISO 10780 and ISO 9096 |

2.3.1.3 Necessary monitoring equipment and techniques should be provided and used to demonstrate that the process is properly operated and the emissions can be minimized to meet the air pollution control requirements. The scope, manner and frequency of the monitoring should be sufficient for this purpose and will be determined by EPD. Monitoring results should be recorded in such manner specified by EPD. The record should be retained at the premises for a minimum of two years, or other period specified by EPD, after the date of last entry and be made available for examination as and when required by EPD.

2.3.1.4 On-line monitoring and periodic measurement shall be carried out and the results shall be properly recorded. Evidence should be provided to demonstrate quality assurance procedures are in place to ensure all monitoring results are sufficiently accurate and reliable. Calibration on the monitoring equipment has to be done by means of parallel measurements with the reference methods as agreed by EPD. The requirements of the on-line monitoring and periodic measurement are provided in the following sections.

2.3.2. On-line Monitoring

2.3.2.1 Continuous monitoring of the in-stack exhaust gas and the process shall be carried out. The continuous monitoring data should be transmitted instantaneously to EPD by telemetry system in such manner and format agreed with EPD. The parameters to be continuously monitored are listed below:-

In-stack Exhaust Gas Continuous Monitoring

á nitrogen oxides

á hydrogen chloride

á hydrogen fluoride

á sulphur dioxide

á opacity

á gaseous and vaporous organic substances

á carbon monoxide

á oxygen

á pressure

á temperature

á water vapour content (The continuous measurement of the water vapour content should not be required if the sampled exhaust gas is dried before the emissions are analysed.)

2.3.3. Process Continuous Monitoring

2.3.2.1 Temperature and oxygen content of the gas at the appropriate location(s) in the combustion chamber to demonstrate the compliance of the requirements set out in paragraphs 4.3.1 to 4.3.4 of EPDÕs Guidance Note on the Best Practicable Means for Incinerators (Municipal Waste Incineration) BPM 12/1

2.3.2.2 Temperature of the gas at the appropriate location(s) in the chimney to demonstrate that the exit temperature of the exhaust gas from the chimney of the incineration process is not less than 80¼C at full load condition

2.3.2.3 Other essential operating parameter(s) which may affect the performance of air pollution control measures

2.3.4. Periodic Measurement

2.3.4.1 To confirm that the levels of dioxin and heavy metals are being adequately controlled, periodic measurements shall be made.

2.3.4.2 The sampling frequency will be determined by EPD. All measurement results should be recorded, processed and presented in a summary report as agreed by EPD. The report should be submitted to EPD without delay after the source sampling(s) as required is/are completed.

2.3.5. Odour Monitoring

2.3.5.1 To determine the effectiveness of the proposed odour mitigation measures and to ensure the odour impacts arising from the operation of the IWMF and the waste reception halls, the waste storage area and mechanical treatment plant meeting the air pollution control requirements, odour monitoring shall be conducted. Odour monitoring involves odour patrols conducted by an odour patrol team. The odour patrol team will patrol and sniff along an odour patrol route along the IWMF site boundary. The implementation of the odour monitoring shall be subject to the prevailing weather forecast condition and no odour monitoring should be carried out during rainy day.

2.3.5.2 The odour patrol team shall be comprised of at least two independent trained personnel / competent persons, who should pass a set of screening tests and fulfil the following requirements:-

á have their individual odour threshold of n-butanol in nitrogen gas in the range of 20 to 80 ppb/v required by the European Standard Method (EN 13725);

á be at least 16 years of age and willing and able to follow instructions;

á be free from any respiratory illnesses;

á not allowed to smoke, eat, drink (except water) or use chewing gum or sweets 30 min before and during odour patrol;

á take great care not to cause any interference with their own perception or that of others by lack of personal hygiene or the use of perfumes, deodorants, body lotions or cosmetics; and

á not communicate with each other about the results of their choices.

2.3.5.3 The independent trained personnel / competent persons should use their noses (olfactory sensors) to sniff odours at different locations. The main odour emission sources and the areas to be affected by the odour nuisance shall be identified. During the patrol, the sequence should generally start from less odorous locations to stronger odorous locations.

2.3.5.4 The perceived odour intensity is divided into 5 levels. Table 2.2 describes the odour intensity for different levels.

Table 2.2 Odour Intensity Level

|

Level |

Odour Intensity |

|

0 |

Not detected. No odour perceived or an odour so weak that it cannot be easily characterised or described |

|

1 |

Slight identifiable odour, and slight chance to have odour nuisance |

|

2 |

Moderate identifiable odour, and moderate chance to have odour nuisance |

|

3 |

Strong identifiable, likely to have odour nuisance |

|

4 |

Extreme severe odour, and unacceptable odour level |

2.3.5.5 The independent trained personnel / competent person shall record the findings including date and time, weather condition (e.g. sunny, fine, cloudy, and rainy), odour intensity, odour nature and possible odour sources, local wind speed, and wind direction at each location. In addition, some relevant meteorological data such as daily average temperature, and daily average humidity on the day of odour patrol shall be obtained from the nearest Hong Kong Observatory station for reference.

2.3.5.6 Odour patrols will be conducted in summer (i.e. from July to September). In the first 2 operational years of the IWMF, monthly odour patrols shall be conducted. Odour patrols shall be carried out during daytime and evening / night time when the IWMF and its waste reception halls, the waste storage area and the mechanical treatment plant are operated under normal operating condition.

2.3.5.7 The need to continue the odour patrol after the end of the 2-year monitoring period would depend on the monitoring results and should be agreed with EPD. If the level of odour intensity at any sniffing location is higher than 1 due to potential odour emission from the IWMF and its waste reception halls, the waste storage area and the mechanical treatment plant in two consecutive months, the odour patrol programme would be extended until the level of odour intensity (that is determined to be due to potential odour emission from the IWMF or the associated facilities) at all the sniffing locations have dropped to 0 in three consecutive months.

2.3.5.8 Table 2.3 shows the action level and limit level to be used for odour patrol. Should any exceedance of the action and limit levels occurs, actions in accordance with the event and action plan in Table 2.4 should be carried out.

Table 2.3 Action and Limit Levels for Odour Nuisance

|

Parameter |

Action Level |

Limit Level |

|

Odour Nuisance (from odour patrol) |

When one documented complaint is received(1), or Odour Intensity of 2 is measured from odour patrol. |

Two or more documented complaints are received(1) within a week; or Odour intensity of 3 or above is measured from odour patrol. |

Note: Once the complaint is received by the Project Proponent (EPD), the Project Proponent shall investigate and verify the complaint whether it is related to the potential odour emission from the IWMF and associated facilities.

Table 2.4 Event and Action Plan for Odour Monitoring

|

EVENT |

ACTION |

|

|

Person-in-charge of Odour Monitoring |

Project Proponent |

|

|

ACTION LEVEL |

||

|

Exceedance of action level (Odour Patrol) |

1. Identify source/reason of exceedance; 2. Repeat odour patrol to confirm finding. |

1. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 week; 2. Rectify any unacceptable practice; 3. Implement more mitigation measures if necessary; 4. Inform EPD. |

|

Exceedance of action level (Odour Complaints) |

1. Identify source/reason of exceedance; 2. Carry out odour patrol to determinate odour intensity. |

1. Carry out investigation and verify the complaint whether it is related to potential odour emission from the IWMF; 2. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 week; 3. Rectify any unacceptable practice; 4. Implement more mitigation measures if necessary; 5. Inform EPD. |

EVENT |

ACTION |

|

|

Person-in-charge of Odour Monitoring |

Project Proponent |

|

|

LIMIT LEVEL |

||

|

Exceedance of Limit level |

1. Identify source/reason of exceedance; 2. Inform EPD; 3. Repeat odour patrol to confirm findings; 4. Increase odour patrol frequency to bi-weekly; 5. Assess effectiveness of remedial action and keep EPD informed of the results; 6. If exceedance stops, cease additional odour patrol. |

1. Carry out investigation to identify the source/reason of exceedance. Investigation should be completed within 2 week; 2. Rectify any unacceptable practice; 3. Formulate remedial actions; 4. Ensure remedial actions properly implemented; 5. If exceedance continues, consider what more/enhanced mitigation measures should be implemented; 6. Inform EPD. |

2.3.5.9 In the event when an odour complaint is received, Project Proponent should liaise with the complainant and register the complaint. The complaint register is to record detailed information regarding the odour complaint so as to facilitate the investigation work. The registration should contain, but not be limited to the following information:-

á Location of where the odour nuisance occurred;

á Date and time of the complaint and the nuisance event;

á Description of the complaint, i.e. the type and characteristics of the odour; and an indication of the odour strength (highly offensive/offensive/slightly offensive/just continuously detectable /intermittently detectable);

á Meteorological conditions from the nearest HK Observatory station at the time of complaint; and

á Name and contact information of the complainant.

3. NOISE IMPACT

3.1. Introduction

3.1.1. In this section, the requirements, methodology, equipment, monitoring locations, criteria and protocols for the monitoring and audit of noise impacts during the construction phase of the Project are presented. The proposed mitigation measures during construction and operation phases of the Project are also described in this section.

3.1.2. Construction noise impacts from this Project are predicted at the identified Noise Sensitive Receivers (NSRs). Noise mitigation measures would be required to reduce noise levels to the stipulated standard. A noise monitoring programme shall be undertaken to ensure such mitigation measures would be implemented properly.

3.2. Noise Parameters

3.2.1. Construction Phase

3.2.1.1 The construction noise level shall be measured in terms of the A-weighted equivalent continuous sound pressure level (Leq). Leq (30 minutes) shall be used as the monitoring parameter for the time period between 0700 and 1900 hours on normal weekdays. For all other time periods, Leq (5 minutes) shall be employed for comparison with the Noise Control Ordinance (NCO) criteria.

3.2.1.2 Supplementary information for data auditing, statistical results such as L10 and L90 shall also be obtained for reference. A sample data record sheet based on the one presented in the EM&A Guidelines for Development Projects in Hong Kong is shown in Appendix 3.1. The ET Leader may modify the data record sheet for this EM&A programme, of which the format should be agreed by the SOR and the IEC.

Monitoring Equipment

3.2.1.3 As referred in the Technical Memorandum (TM) issued under the NCO, sound level meters in compliance with the International Electrotechnical Commission Publications 651: 1979 (Type 1) and 804: 1985 (Type 1) specifications shall be used for carrying out the noise monitoring. Immediately prior to and following each noise measurement, the accuracy of the sound level meter shall be checked using an acoustic calibrator generating a known sound pressure level at a known frequency. Measurements may be accepted as valid only if the calibration levels from before and after the noise measurement agree to within 1.0 dB

3.2.1.4 Noise measurements shall not be made in fog, rain, wind with a steady speed exceeding 5m/s or wind with gusts exceeding 10 m/s. The wind speed shall be checked with a portable wind speed meter capable of measuring the wind speed in m/s.

3.2.1.5 The ET is responsible for the provision of the monitoring equipment. He shall ensure that sufficient noise measuring equipment and associated instrumentation are available for carrying out the baseline monitoring, regular impact monitoring and ad hoc monitoring. All the equipment and associated instrumentation shall be clearly labelled.

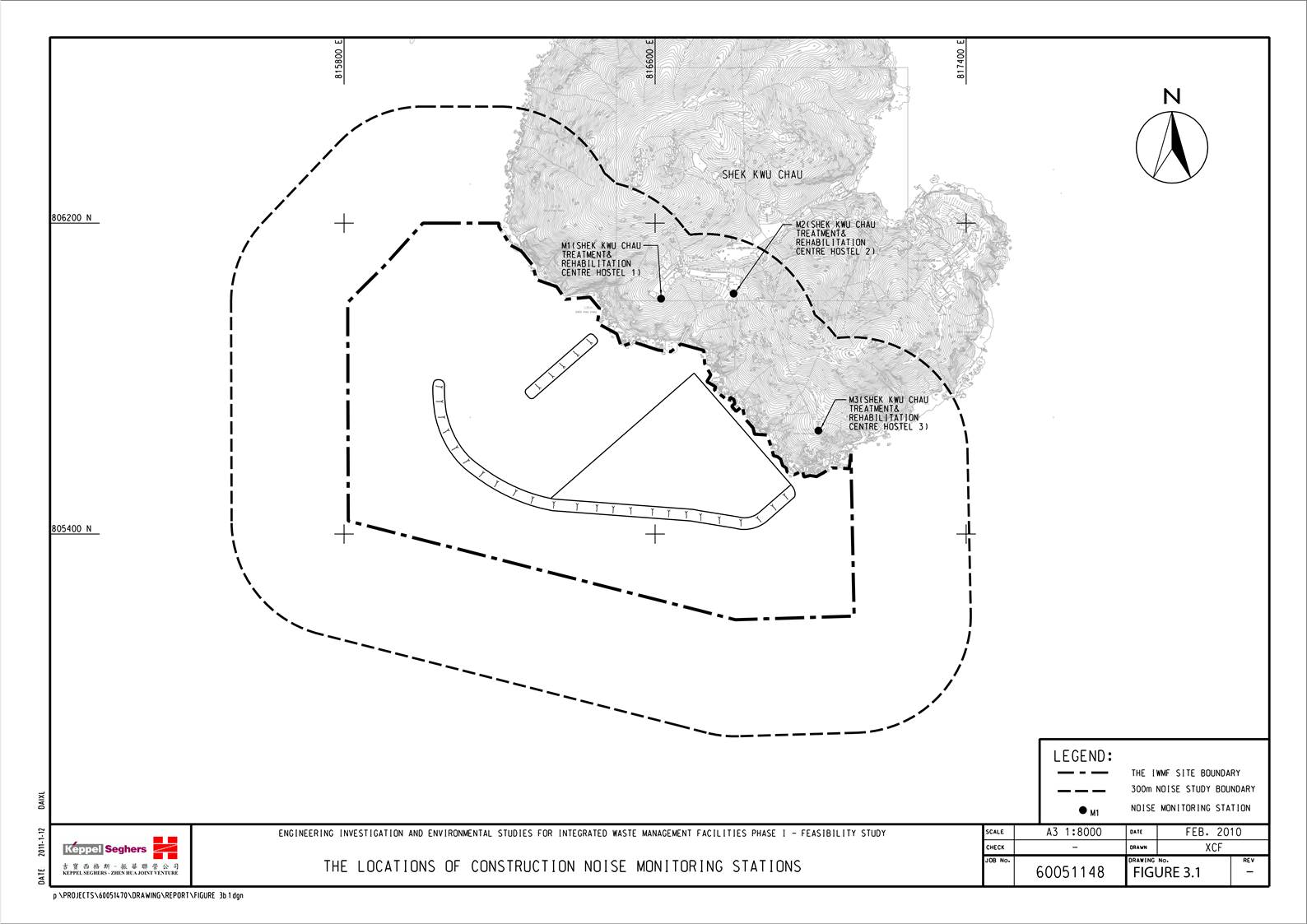

3.2.1.6 The locations of construction noise monitoring stations are summarized in Table 3.1 and shown in Figure 3.1. These locations represent the worst affected sensitive receivers during construction phase of the Project.

Table 3.1 The Locations of Construction Noise Monitoring Station

|

Station |

NSR ID in EIA Report |

Noise Monitoring Location |

|

M1 |

N_S1 |

Shek Kwu Chau Treatment & Rehabilitation Centre Hostel 1 |

|

M2 |

N_S2 |

Shek Kwu Chau Treatment & Rehabilitation Centre Hostel 2 |

|

M3 |

N_S3 |

Shek Kwu Chau Treatment & Rehabilitation Centre Hostel 3 |

3.2.1.7 The status and locations of noise sensitive receivers may change after issuing this Manual. If such case exists, the ET Leader shall propose updated monitoring locations and seek approval from EPD and agreement from the SOR and the IEC before baseline monitoring commences.

3.2.1.8 When alternative monitoring locations are proposed, the monitoring locations shall be chosen based on the following criteria:

á Monitoring at sensitive receivers close to the major site activities which are likely to have noise impacts;

á Monitoring at the noise sensitive receivers as defined in the Technical Memorandum; and

á Assurance of minimal disturbance to the occupants during monitoring.

3.2.1.9 The monitoring station shall normally be at a point 1 m from the exterior of the sensitive receiver building facade and be at a position 1.2 m above the ground. If there is problem with access to the normal monitoring position, an alternative position may be chosen, and a correction to the measurements shall be made. For reference, a correction of +3 dB(A) shall be made to the free field measurements. The ET shall agree with the IEC on the monitoring position and the corrections adopted. Once the positions for the monitoring stations are chosen, the baseline monitoring and the impact monitoring shall be carried out at the same positions.

3.3. Baseline Monitoring

3.3.1. Construction Phase

3.3.1.1 The ET shall carry out baseline noise monitoring prior to the commencement of the construction works. The baseline monitoring shall be carried out daily for a period of at least two weeks. Before commencing the baseline monitoring, the ET shall develop and submit to the IEC the baseline monitoring programme such that the IEC can conduct on-site audit to ensure accuracy of the baseline monitoring results.

3.3.1.2 There shall not be any construction activities in the vicinity of the stations during the baseline monitoring.

3.3.1.3 In exceptional cases, when insufficient baseline monitoring data or questionable results are obtained, the ET Leader shall liaise with the SOR, EPD and IEC to agree on an appropriate set of data to be used as a baseline reference and submit to the SO and IEC for agreement and EPD for approval.

3.4. Impact Monitoring

3.4.1. Construction Phase

3.4.1.1 Noise monitoring shall be carried out at all the designated monitoring stations. The monitoring frequency shall depend on the scale of the construction activities. The following is an initial guide on the regular monitoring frequency for each station on a weekly basis when noise generating activities are underway:

á One set of measurements between 0700 and 1900 hours on normal weekdays.

3.4.1.2 If construction works are extended to include works during the hours of 1900 Ð 0700 as well as public holidays and Sundays, additional weekly impact monitoring shall be carried out during respective restricted hours periods. Applicable permits under NCO shall be obtained by the Contractor.

3.4.1.3 If a school exists near the construction activity, noise monitoring shall be carried out at the monitoring stations for the schools during the school examination periods. The ET Leader shall liaise with the schoolÕs personnel and the Examination Authority to ascertain the exact dates and times of all examination periods during the course of the contract.

3.4.1.4 In case of non-compliance with the construction noise criteria, more frequent monitoring as specified in the Action Plan shall be carried out. This additional monitoring shall be continued until the recorded noise levels are rectified or demonstrated to be unrelated to the construction activities.

3.5.1. Construction Phase

3.5.1.1 The Action and Limit levels for construction noise are defined in Table 3.2. Should non-compliance of the criteria occur, action in accordance with the Event and Action Plan in Table 3.3 shall be implemented.

Table 3.2 Action and Limit Levels for Construction Noise

|

Time Period |

Action Level |

Limit Level |

|

0700 Ð 1900 hours on normal weekdays |

When one documented complaint is received |

75 dB(A) |

Notes: If works are to be carried out during restricted hours, the conditions stipulated in the Construction Noise Permit (CNP) issued by the Noise Control Authority have to be followed.

3.6. Mitigation Measure

3.6.1. Construction Phase

3.6.1.1 To alleviate the construction noise impact on the affected NSRs, movable noise barriers and acoustic mats are proposed to be provided for particular items of plant and construction works. It is anticipated that a movable noise barrier with a cantilevered upper portion located within 5m from any static or mobile plant can provide 5 dB(A) noise reduction for mobile plant and 10 dB(A) noise reduction for static plant. The barrier material shall have a surface mass of not less than 14 kg/m2 on skid footing with 25 mm thick internal sound absorptive lining to achieve the maximum screening effect.

3.6.1.2 In addition, the good site practices listed below shall be adopted by all the Contractors to further ameliorate the noise impacts.

á Only well-maintained plant should be operated on-site and plant should be serviced regularly during the construction program.

á Silencers or mufflers on construction equipment should be utilised and should be properly maintained during the construction program.

á Mobile plant, if any, should be sited as far away from NSRs as possible.

á Machines and plant (such as trucks) that may be in intermittent use should be shut down between works periods or should be throttled down to a minimum.

á Plant known to emit noise strongly in one direction should, wherever possible, be orientated so that the noise is directed away from the nearby NSRs.

á Material stockpiles and other structures should be effectively utilised, wherever practicable, in screening noise from on-site construction activities.

3.6.1.3 If the above measures are not sufficient to restore the construction noise quality to acceptable levels upon the advice of ET Leader, the contractor shall liaise with the ET Leader to identify further mitigation measures. They shall be proposed to SOR for approval, and the contractor shall then implement these additional mitigation measures.

3.6.2. Operation Phase

3.6.2.1 The Contractor should carry out a noise commissioning test for all fixed noise sources before operation of the Project, in order to ensure compliance of the operational airborne noise levels with the TMÕs stipulated noise standard.

Table 3.3 Event and Action Plan for Construction Noise

|

Event |

Actions to be taken by Environmental Team as immediate as practicable |

Actions to be taken by Independent Environmental Checker as immediate as practicable |

Actions to be taken by Supervising OfficerÕs Representative as immediate as practicable |

Actions to be taken by Contractor as immediate as practicable |

||||

|

Action Level being exceeded |

1. 2. 3.

4.

5.

|

Notify IEC and Contractor; Carry out investigation; Report the results of investigation to the IEC, SO and Contractor; Discuss with the IEC and Contractor on remedial measures required; Increase monitoring frequency to check mitigation effectiveness. (The above actions should be taken within 2 working .days after the exceedance is identified) |

1.

2.

3. |

Review the investigation results submitted by the ET; Review the proposed remedial measures by the Contractor and advise the SO accordingly; Advise the SO on the effectiveness of the proposed remedial measures. (The above actions should be taken within 2 working days after the exceedance is identified). |

1.

2. 3.

4.

|

Confirm receipt of notification of failure in writing; Notify Contractor; In consolidation with the IEC, agree with the Contractor on the remedial measures to be implemented; Supervise the implementation of remedial measures. (The above actions should be taken within 2 working days after the exceedance is identified). |

1.

2. |

Submit noise mitigation proposals to IEC and SO; Implement noise mitigation proposals. (The above actions should be taken within 2 working days after the exceedance is identified) |

|

Limit Level being exceeded |

1. 2.

3. 4.

5.

6.

7.

8.

|

Inform IEC, SO, Contractor and EPD; Repeat measurements to confirm findings; Increase monitoring frequency; Identify source and investigate the cause of exceedance; Carry out analysis of ContractorÕs working procedures; Discuss with the IEC, Contractor and SO on remedial measures required; Assess effectiveness of ContractorÕs remedial actions and keep IEC, EPD and SO informed of the results; If exceedance stops, cease additional monitoring. (The above actions should be taken within 2 working days after the exceedance is identified)

|

1.

2.

|

Discuss amongst SO, ET, and Contractor on the potential remedial actions; Review Contractors remedial actions whenever necessary to assure their effectiveness and advise the SO accordingly; (The above actions should be taken within 2 working days after the exceedance is identified)

|

1.

2. 3.

4.

5.

|

Confirm receipt of notification of failure in writing; Notify Contractor; In consolidation with the IEC, agree with the Contractor on the remedial measures to be implemented; Supervise the implementation of remedial measures; If exceedance continues, consider stopping the Contractor to continue working on that portion of work which causes the exceedance until the exceedance is abated. (The above actions should be taken within 2 working days after the exceedance is identified) |

1.

2.

3.

4.

5.

|

Take immediate action to avoid further exceedance; Submit proposals for remedial actions to IEC and SO within 3 working days of notification; Implement the agreed proposals; Submit further proposal if problem still not under control; Stop the relevant portion of works as instructed by the SO until the exceedance is abated. (The above actions should be taken within 2 working days after the exceedance is identified) |

4. WATER QUALITY IMPACT

4.1. Introduction

4.1.1. This section describes the requirements for the monitoring and audit of water quality impacts from the Project.

4.1.2 The water quality assessment undertaken in the EIA Study has identified that suspended solids would be the most critical water quality parameter during the construction stage. Marine water quality monitoring for suspended solids / turbidity and dissolved oxygen is therefore recommended to be carried out at the nearby water sensitive receivers (WSRs). The monitoring should include baseline and impact monitoring. The impact monitoring should be carried out during the proposed reclamation and breakwater construction. Monitoring programme to be implemented for protection of the coral communities are provided in Section 6.

4.1.3 Regular site inspections were recommended to be undertaken to inspect the construction activities and works areas and also the status on the implementation of the recommended mitigation measures. Discharges of drainage water from the construction works areas would be required to comply with the terms and conditions of a discharge licence, issued by EPD, under the Water Pollution Control Ordinance (WPCO). It may be a stipulation of the WPCO licence to require the Contractor to monitor the quality / quantity of the discharge to show compliance with the conditions of the licence. Such monitoring would not form part of the EM&A programme.

4.1.4 As measure to control the dispersion of filling material from the reclamation area, a silt curtain system would be applied at the marine access opening during the reclamation work. A pilot test should be carried out at the early stage of reclamation to verify the silt-removal efficiency of the silt curtain at marine access opening.

4.1.5 During the operation phase of the Project, all generated wastewater will be discharged into an on-site wastewater treatment plant. The treated effluent from the wastewater treatment plant will be reused for washdown and landscape irrigation in the IWMF site. A Ônet zero dischargeÕ scheme will be adopted during the operation of the IWMF. Saline water would be discharged from the proposed desalination plant. Monitoring of the change in salinity would be required during the commissioning period of the IWMF.

4.2. Water Quality Parameters

4.2.1 Dissolved oxygen (DO), salinity, turbidity and suspended solids (SS) levels shall be monitored at designated marine water quality monitoring stations before, during and after the marine construction works. The levels of DO, pH, salinity, temperature and turbidity should be measured in situ whereas SS should be determined by laboratory.

4.3. Monitoring Locations

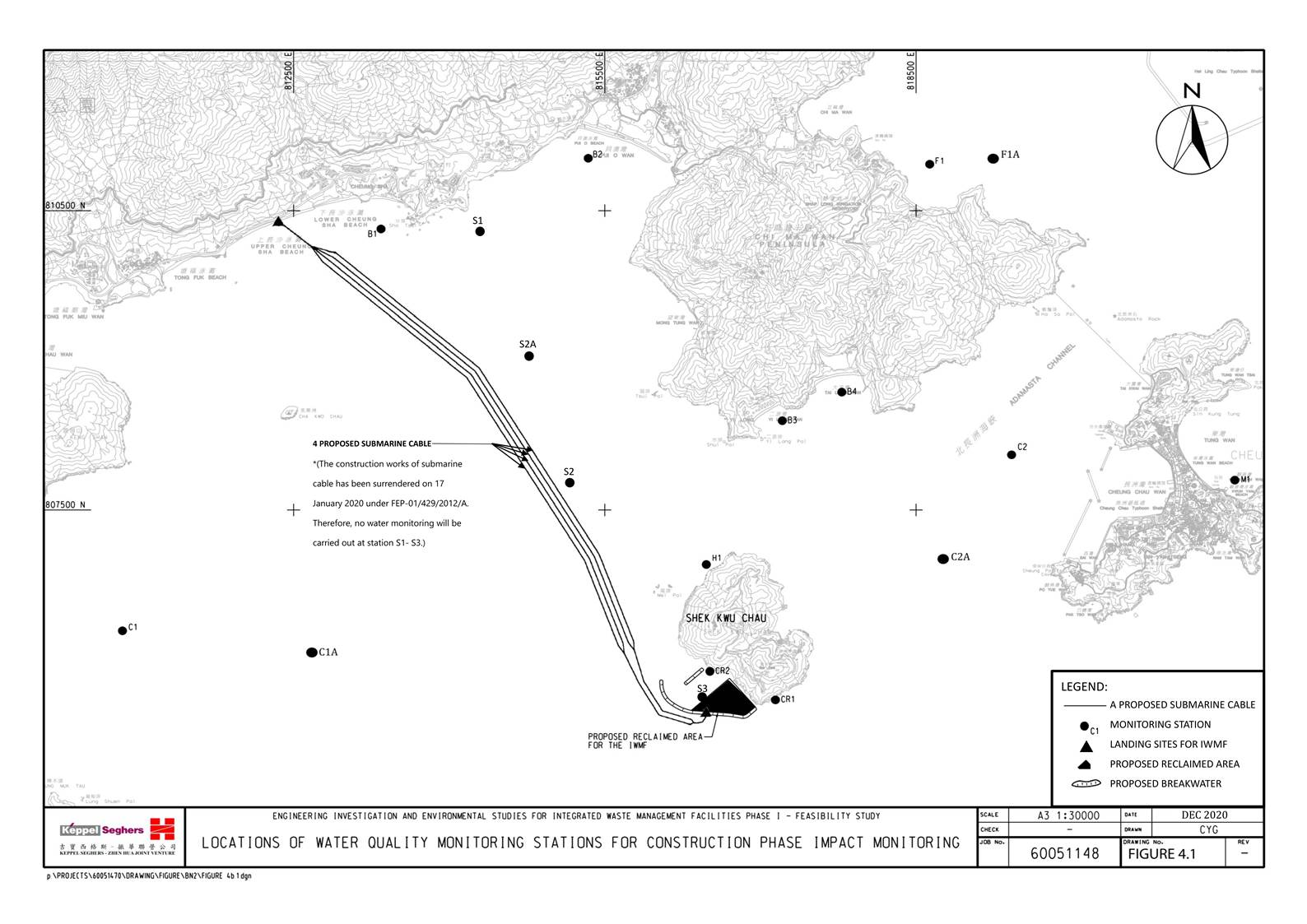

4.3.1 The proposed water quality monitoring stations for construction phase impact assessment are shown in Table 4.1 and Figure 4.1. The status and locations of water sensitive receivers and the marine activities may change after issuing this Manual. If such case exists, the ET Leader shall propose updated monitoring locations and seek approval from the IEC and EPD.

4.3.2 Marine water quality monitoring stations have been proposed at different water quality sensitive receivers to monitor the water quality impact due to the proposed marine works under this Project. Monitoring stations B1 to B4 would be located at 4 beaches respectively at the southern shore of Lantau Island. Monitoring station H1 is located at the horseshoe crab habitat at northern SKC, while CR1 and CR2 are located at the coral communities at southwestern shore of SKC. Monitoring station F1 is located at the Cheung Sha Wan Fish Culture Zone while monitoring station M1 is located at Tung Wan at Cheung Chau. Water quality monitoring at the northern landing site, midway and southern landing site of the proposed submarine cable is proposed at monitoring stations S1, S2 and S3 for monitoring the SS impact due to the laying of submarine cable. Control stations C1 and C2 have been proposed at far field location for comparison. Under the further FEP-01/429/2012/A, the construction works of submarine cable has been surrendered on 17 January 2020. Therefore, no monitoring will be carried out at monitoring stations S1-S3. As existing monitoring locations C1 and C2 are situated at fairway and F1 is located inside Cheung Sha Wan fish culture zone, marine safety concern and concerns from other stakeholders have been raisen. In order to clear up stakeholdersÕ worries, it is thus proposed to relocate C1, C2 and F1 water monitoring location to new locations named as C1A, C2A and F1A as shown in Table 4.1 and Figure 4.2. Those new proposed locations C1A are equivlant to the orginal monitoring stations C1, C2 and F1 respectively, furthermore, those updated locations are verified by IEC and approved by EPD accordingly.

Table 4.1 Proposed Marine Water Quality Stations for Baseline and Impact Monitoring during Construction Phase

|

Station |

Description |

Easting |

Northing |

|

B1 |

Beach - Cheung Sha Lower |

813342 |

810316 |

|

B2 |

Beach - Pui O |

815340 |

811025 |

|

B3 |

Beach - Yi Long Wan |

817210 |

808395 |

|

B4 |

Beach - Tai Long Wan |

817784 |

808682 |

|

H1 |

Horseshoe Crab - Shek Kwu Chau |

816477 |

806953 |

|

C1A# |

Control Station |

812823 |

806300 |

|

C2A# |

Control Station |

818869 |

806808 |

|

F1A# |

Cheung Sha Wan Fish Culture Zone |

819109 |

810924 |

|

S1* |

Submarine Cable Landing Site |

814245 |

810335 |

|

S2A*# |

Submarine Cable |

814808 |

808515 |

|

S3* |

Submarine Cable Landing Site |

816420 |

805621 |

|

CR1 |

Coral |

817144 |

805597 |

|

CR2 |

Coral |

816512 |

805882 |

|

M1 |

Tung Wan |

821572 |

807799 |

Note: * Under the further FEP-01/429/2012/A, the construction works of submarine cable has been surrendered on 17 January 2020. Therefore, no monitoring will be carried out at monitoring stations S1-S3.

# The monitoring stations were relocated from the organial locations to address stakeholder concerns.

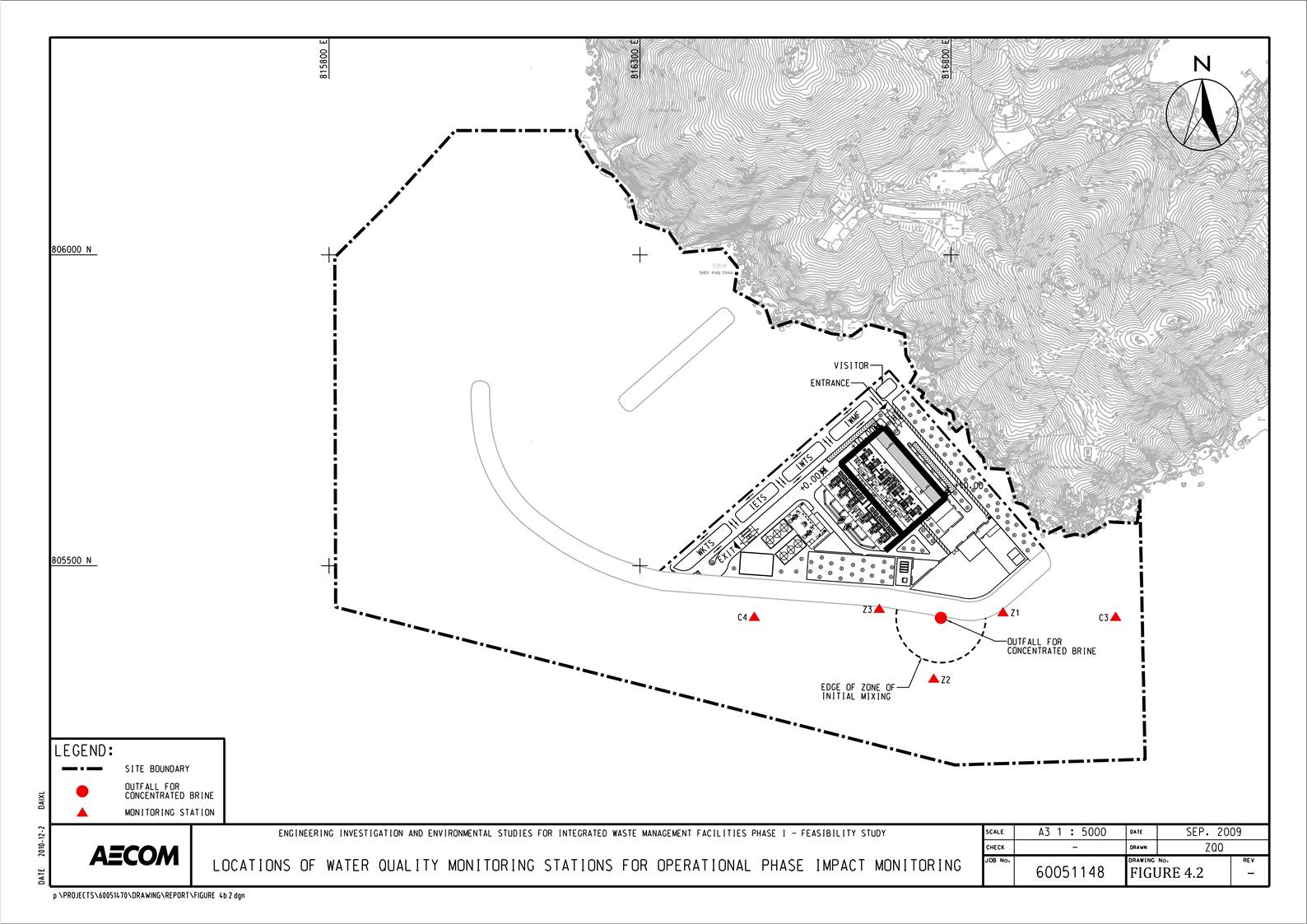

4.3.3 The proposed water quality monitoring stations for operational phase impact assessment are shown in Table 4.2 and Figure 4.2. The monitoring stations proposed in this section are indicative only and may be subjected to further review before commencement of the water quality monitoring works. The locations of brine water outfall may change after issuing this Manual. If such case exists, the ET Leader shall propose updated monitoring locations and seek approval from the IEC and EPD.

4.3.4 Marine water quality monitoring stations have been proposed near the saline water outfall to monitor the water quality impact due to the proposed saline water discharge. Monitoring stations Z1 to Z3 would be located near the eastern, southern and western edge of the zone of initial mixing based on the results of modelling work conducted under this EIA. Control stations C3 and C4 have been proposed at far field location for comparison.

Table 4.2 Proposed Marine Water Quality Stations for Baseline and Impact Monitoring during Operational Phase

|

Station |

Description |

Easting |

Northing |

|

Z1 |

Near the Edge of ZID** (east of the brine water outfall) |

816883 |

805424 |

|

Z2 |

Near the Edge of ZID (south of the brine water outfall) |

816772 |

805317 |

|

Z3 |

Near the Edge of ZID (west of the brine water outfall) |

816685 |

805429 |

|

C3 |

Control Station |

817065 |

805416 |

|

C4 |

Control Station |

816484 |

805416 |

Note: **ZID refers to ÒZone of Initial MixingÓ

4.3.5 Sampling for baseline and impact monitoring shall be taken at three water depths, namely, 1m below water surface, mid-depth and 1m above seabed, except at where the water depth is less than 6m, in which case the mid-depth station may be omitted. Shall the water depth be less than 3m, only the mid-depth station will be monitored.

4.4. Baseline Monitoring

4.4.1 Construction Phase

4.4.1.1 Baseline conditions for marine water quality should be established and agreed with EPD prior to the commencement of marine works. The purpose of the baseline monitoring is to establish ambient conditions prior to the commencement of the marine works and to demonstrate the suitability of the proposed monitoring stations.

4.4.1.2 The baseline conditions should be established by measuring suspended solids (SS), salinity, turbidity and dissolved oxygen (DO) levels at the selected monitoring stations as shown in Table 4.3. The baseline monitoring schedule should be submitted to EPD at least 4 weeks before commencement of monitoring for agreement. EPD should also be notified immediately for any changes in schedule.

4.4.1.3 The measurements should be taken at all designated monitoring stations, 3 days per week, at mid-flood and mid-ebb tides, for at least 4 weeks prior to the commencement of marine works. There should not be any marine construction activities in the vicinity of the stations during the baseline monitoring. The interval between 2 sets of monitoring should not be less than 36 hours. Duplicate in-situ measurements and water sampling should be carried out in each sampling event.

4.4.1.4 To study the potential variations in the water quality within a year due to natural fluctuations, baseline monitoring shall be conducted for both dry season (October Ð March) and wet season (April Ð September).

4.4.1.5 The baseline monitoring report should be submitted to EPD at least 4 weeks before the commencement of the marine works for agreement. The baseline monitoring report should be certified by the ET Leader and verified by IEC before submission to EPD.

4.4.2 Operational Phase

4.4.2.1 Baseline conditions for marine water quality should be established and agreed with EPD prior to the commission of the brine water discharge. The purpose of the baseline monitoring is to establish ambient conditions prior to the commission of the brine water discharge.

4.4.2.2 The baseline conditions should be established by measuring salinity at the selected monitoring stations as shown in Table 4.4. The baseline monitoring schedule should be submitted to EPD at least 4 weeks before commencement of monitoring for agreement. EPD should also be notified immediately for any changes in schedule.

4.4.2.3 The measurements should be taken at all designated monitoring stations, 3 days per week, at mid-flood and mid-ebb tides, for at least 4 weeks prior to the commission of the brine water discharge. There should not be any marine construction activities in the vicinity of the stations during the baseline monitoring. The interval between 2 sets of monitoring should not be less than 36 hours. Duplicate in-situ measurements should be carried out in each sampling event.

4.4.2.4 The baseline monitoring report should be submitted to EPD at least 4 weeks before the commission of the brine water discharge for agreement. The baseline monitoring report should be certified by the IEC before submission to EPD.

4.5 Impact Monitoring

4.5.1 Construction Phase

4.5.1.1 During the period of marine construction, monitoring should be undertaken three days per week, at mid-flood and mid-ebb tides, with sampling / measurement at the designated monitoring stations as shown in Table 4.1. Upon completion of the marine works, the monitoring exercise at the designated monitoring locations should be continued for four weeks in the same manner as the baseline monitoring.

4.5.1.2 The interval between two sets of monitoring should not be less than 36 hours except where there are exceedances of Action and/or Limit Levels, in which case the monitoring frequency will be increased. Table 4.3 shows the proposed monitoring frequency and water quality parameters. Duplicate in-situ measurements and water sampling should be carried out in each sampling event. The monitoring probes should be retrieved out of water after the first measurement and then redeployed for the second measurement. Where the difference in value between the first and second readings of DO or turbidity is more than 25% of the value of the first reading, the reading should be discarded and further readings should be taken.

4.5.1.3 The proposed water quality monitoring schedule should be submitted to EPD at least 1 week before the first day of the monitoring month. EPD should also be notified immediately for any changes in schedule. If the monitoring data collected at the designated stations indicate that the Action or Limit Levels as shown in Table 4.6 are exceeded, appropriate actions should be taken in accordance with the Event and Action Plan in Table 4.7.

Table 4.3 Proposed Marine Water Quality Monitoring Frequency and Parameters for Construction Phase Impact Monitoring

|

Activities |

Monitoring Frequency |

Key Parameters Note 1 |

Monitoring Stations |

|

During the 4-week baseline monitoring period |

Three days per week, at mid-flood and mid-ebb tides |

Suspended Solids (SS), Turbidity and Dissolved Oxygen (DO) |

B1, B2, B3, B4, H1, C1A, C2A, F1A, S1, S2A, S3, CR1, CR2, M1 |

|

During marine works for proposed reclamation / breakwater construction |

Three days per week, at mid-flood and mid-ebb tides |

Suspended Solids (SS), Turbidity and Dissolved Oxygen (DO) |

B1, B2, B3, B4, H1, C1A, C2A, F1A, CR1, CR2, M1 |

|

During a 4-week period after completion of marine works |

Three days per week, at mid-flood and mid-ebb tides |

Suspended Solids (SS), Turbidity and Dissolved Oxygen (DO) |

B1, B2, B3, B4, H1, C1A, C2A, F1A, CR1, CR2, M1 |

Note: 1. DO and turbidity should be measured in-situ whereas SS should be determined by laboratory analysis.

4.5.2 Operational Phase

4.5.2.1 When the discharge of brine water from the desalination plant start, monitoring should be undertaken three days per week, at mid-flood and mid-ebb tides, with measurement at the designated monitoring stations as shown in Table 4.2. The monitoring exercise at the designated monitoring locations should be continued for at least four weeks.

4.5.2.2 The interval between two sets of monitoring should not be less than 36 hours except where there are exceedances of Action and/or Limit Levels, in which case the monitoring frequency will be increased. Table 4.4 shows the proposed monitoring frequency and water quality parameters. Duplicate in-situ measurements should be carried out in each sampling event. The monitoring probes should be retrieved out of water after the first measurement and then redeployed for the second measurement. Where the difference in value between the first and second readings of salinity is more than 25% of the value of the first reading, the reading should be discarded and further readings should be taken.

Table 4.4 Proposed Marine Water Quality Monitoring Frequency and Parameters for Operational Phase Impact Monitoring

|

Activities |

Monitoring Frequency |

Key Parameters Note 1 |

Monitoring Stations |

|

During the 4-week baseline monitoring period |

Three days per week, at mid-flood and mid- ebb tides |

Salinity |

Z1, Z2, Z3, C3, C4 |

|

During the first 4 weeks of the commission of brine water discharge |

Three days per week, at mid-flood and mid- ebb tides |

Salinity |

Z1, Z2, Z3, C3, C4 |

Note: 1. Salinity should be measured in situ.

4.5.2.3 The proposed water quality monitoring schedule should be submitted to EPD at least 1 week before the first day of monitoring. EPD should also be notified immediately for any changes in schedule. If the monitoring data collected at the designated stations indicate that the Action or Limit Levels as shown in Table 4.6 are exceeded, appropriate actions should be taken in accordance with the Event and Action Plan in Table 4.8.

4.6 Efficiency of Silt Curtain at Marine Access Opening

4.6.1 The ET shall be responsible for conducting tests to confirm that the silt curtain systems to be adopted at marine access opening for reclamation filling work would achieve the silt removal efficiency stated in the EIA Report.

4.6.2 A method statement shall be submitted by the ET Leader to seek approval from the IEC and EPD.

4.6.3 During the initial period of filling works for reclamation at the SKC site, the silt-removal efficiency of the silt-curtains shall be verified by examining the results of water quality monitoring points. The water quality monitoring points to be selected for the pilot test shall be those close to the marine access opening for the reclamation filling works. The details for the pilot study shall be agreed by EPD.

4.6.4 Pilot tests should be carried out during the early stage of reclamation to confirm whether the silt removal efficiency of the silt curtain systems at marine access opening can achieve at least 80% silt removal efficiency for reclamation filling. The pilot test shall include basic measurements such as turbidity and suspended solids as well as current speed and direction.

4.6.5 Regardless of the measured efficiency of the silt curtain system, the event and action plan shall only be based on the monitoring results at the designed monitoring stations.

4.7 Site Audits

4.7.1 Implementation of regular site audits is to ensure that the recommended mitigation measures are to be properly undertaken during proposed construction works. It can also provide an effective control of any malpractices and therefore achieve continual improvement of environmental performance on site.

4.7.2 Site audits shall be carried out by the ET and shall be based on the mitigation measures for water pollution control recommended in the implementation schedule as presented in Appendix 11.1. In the event that the recommended mitigation measures are not fully or properly implemented, deficiency shall be recorded and reported to the site management. Suitable actions are to be carried out to:

á investigate the problems and the causes;

á issue action notes to the Contractor who is responsible for the works;

á implement remedial and corrective actions immediately;

á re-inspect the site conditions upon completion of the remedial and corrective actions; and

á record the event and discuss with the Contractor for preventive actions.

4.7.3 Daily site audit including full-time on-site monitoring by the ET is required during the dredging for anti-scouring protection layer for checking the compliance with the permitted maximum daily dredging rate and its respective distance from the nearest non-translocatable coral community by the dredging contractor as specified in S.2.18 of the Further Environmental Permit (no.:FEP-01/429/2012/A).

4.8 Field Log

4.8.1 Other relevant data should also be recorded, including monitoring location / position, time, water depth, sampling depth, pH, salinity, DO saturation, water temperature, tidal stages, weather conditions and any special phenomena or work underway nearby.

4.8.2 A sample data record sheet is shown in Appendix 4.1 for reference.

4.9 Monitoring Equipment

Dissolved Oxygen and Temperature Measuring Equipment

4.9.1 The instrument should be a portable and weatherproof DO measuring instrument complete with cable and sensor, and use a DC power source. The equipment should be capable of measuring:

á A DO level in the range of 0 ‑ 20 mg/L and 0 ‑ 200% saturation; and

á Temperature of 0 ‑ 45 degree Celsius.

Turbidity Measurement Instrument

4.9.2 The instrument should be a portable and weatherproof turbidity-measuring instrument using a DC power source. It should have a photoelectric sensor capable of measuring turbidity between 0 - 1000 NTU (for example, Hach model 2100P or an approved similar instrument).

pH Measurement Instrument

4.9.3 The instrument should consist of a potentiometer, a glass electrode, a reference electrode and a temperature-compensating device. It should be readable to pH in a range of 0 to 14. Standard buffer solutions of at least pH 7 and pH 10 should be used for calibration of the instrument before and after use.

Sampler

4.9.4 A water sampler is required. It should comprise a transparent PVC cylinder, with a capacity of not less than 2 litres, which can be effectively sealed with latex cups at both ends. The sampler should have a positive latching system to keep it open and prevent premature closure until released by a messenger when the sampler is at the selected water depth (for example, Kahlsico Water Sampler or an approved similar instrument).

Water Depth Detector

4.9.5 A portable, battery-operated echo sounder should be used for the determination of water depth at each designated monitoring station. This unit can either be hand held or affixed to the bottom of the work boat, if the same vessel is to be used throughout the monitoring programme.

Salinity

4.9.6 A portable salinometer capable of measuring salinity in the range of 0-40 parts per thousand (ppt) shall be provided for measuring salinity of the water at each monitoring location.

Sample Containers and Storage

4.9.7 Water samples for SS should be stored in high density polythene bottles with no preservative added, packed in ice (cooled to 4¡C without being frozen) and delivered to the laboratory and analysed as soon as possible after collection. Sufficient volume of samples should be collected to achieve the detection limit stated in Section 4.10.

Monitoring Position Equipment

4.9.8 A hand-held or boat-fixed type digital Differential Global Positioning System (DGPS) with way point bearing indication and Radio Technical Commission for maritime (RTCM) Type 16 error message Ôscreen pop-upÕ facilities (for real-time auto-display of error messages and DGPS corrections from the Hong Kong Hydrographic Office), or other equipment instruments of similar accuracy, should be provided and used to ensure that the water sampling locations are correct during the water quality monitoring work.

Calibration of In-Situ Instruments

4.9.9 The DO meter and turbidimeter should be checked and calibrated before use. DO meter and turbidimeter should be certified by a laboratory accredited under HOKLAS or any other international accreditation scheme, and subsequently re-calibrated at three monthly intervals throughout all stages of the water quality monitoring. Responses of sensors and electrodes should be checked with certified standard solutions before each use. Wet bulb calibration for a DO meter should be carried out before and after all measurements on each monitoring day which is considered adequate for the type of DO meter employed.

4.9.10 Sufficient stocks of spare parts should be maintained for replacements when necessary. Backup monitoring equipment should also be made available so that monitoring can proceed uninterrupted even when some equipment is under maintenance, calibration, etc.

4.10 Laboratory Measurement / Analysis